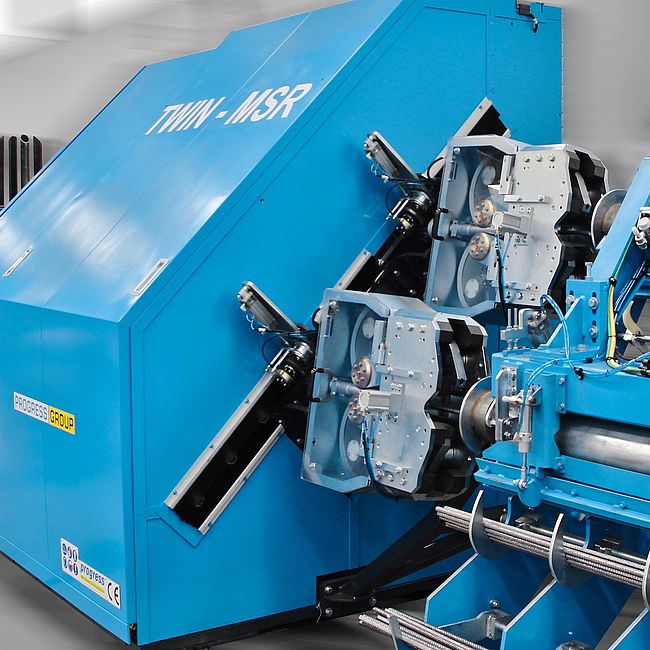

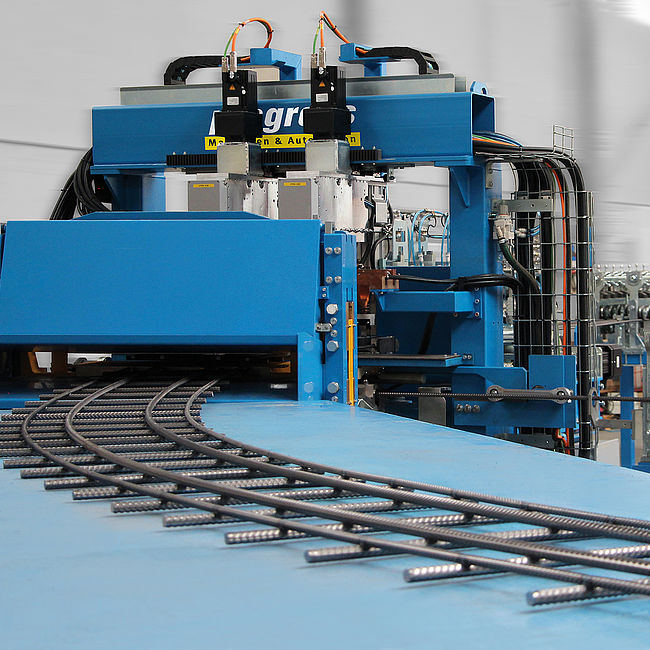

Mesh welding plants

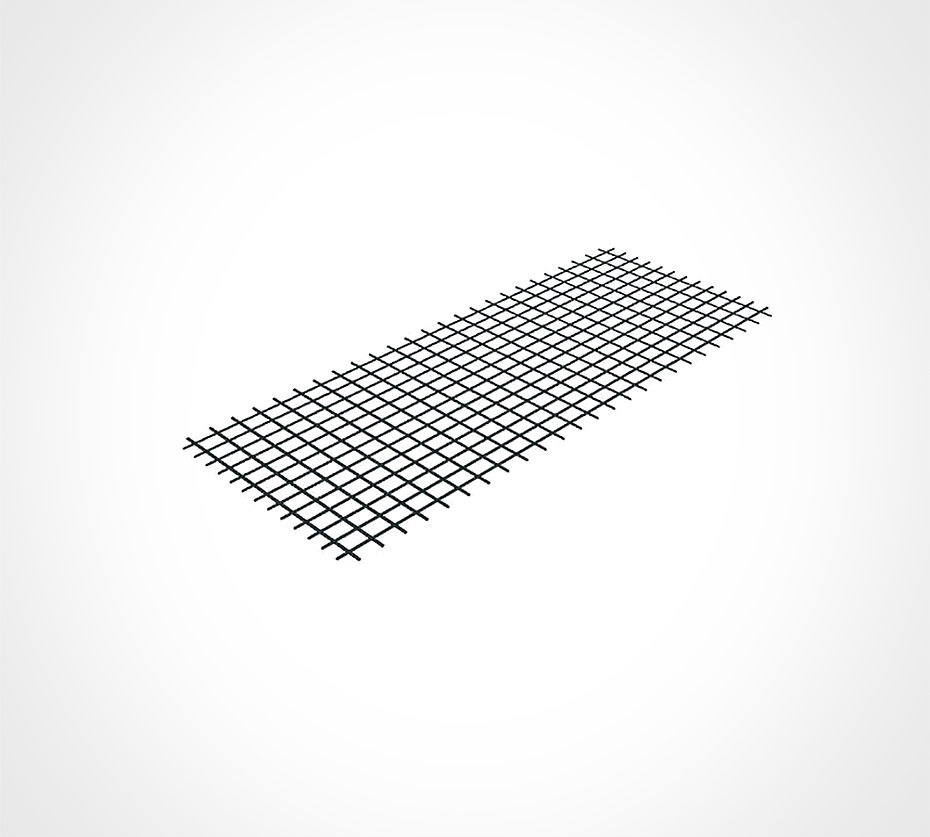

With our mesh welding plants you have the option of welding tailor-made bespoke mesh from coil. The mesh welding plants' strengths lie in their versatility and in the infinite number of possibilities for adapting them to the needs of the individual customer.

Machine features:

- Production of tailor-made mesh

- Increased cost-effectiveness and reduced staffing requirements

- No clippings

- Design flexibility for the plant

- Compact, requires little space

- Manageable maintenance costs

- Ease of operation and good EDP networking

- Upgrade of other components available at any time

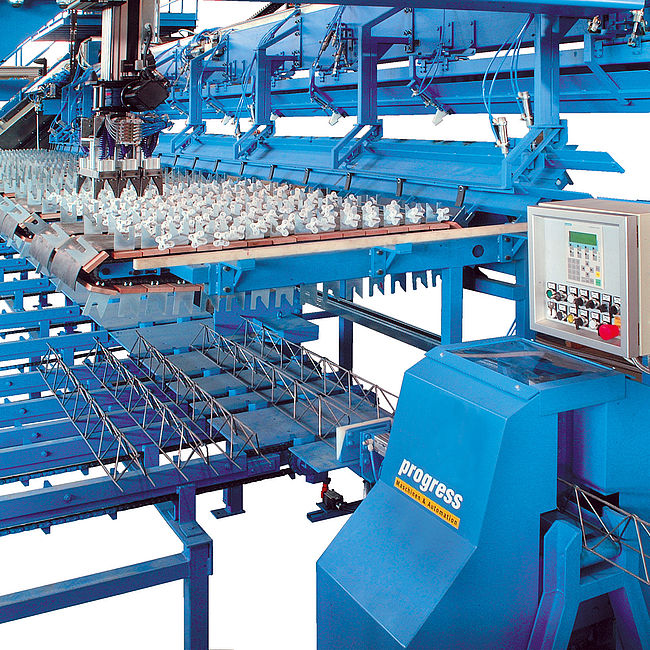

To maximise productivity, we have developed the perfect software package for mesh welding plants.

Flexible just-in-time production

Efficiency and cost-effectiveness

Integral bending and logistics systems

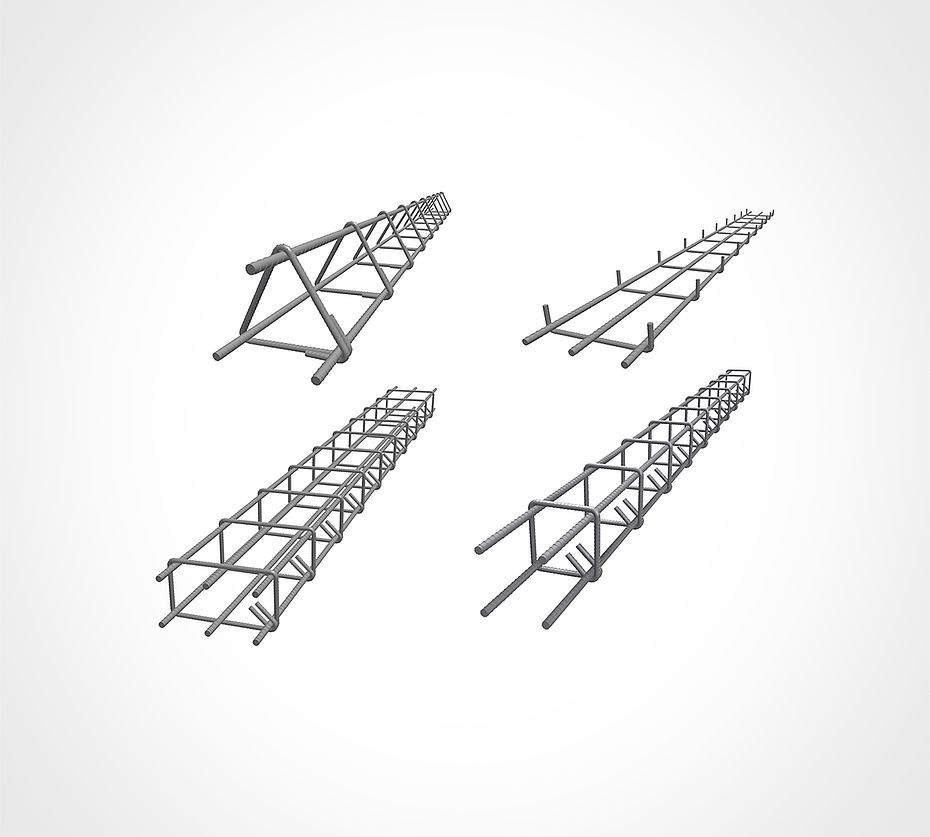

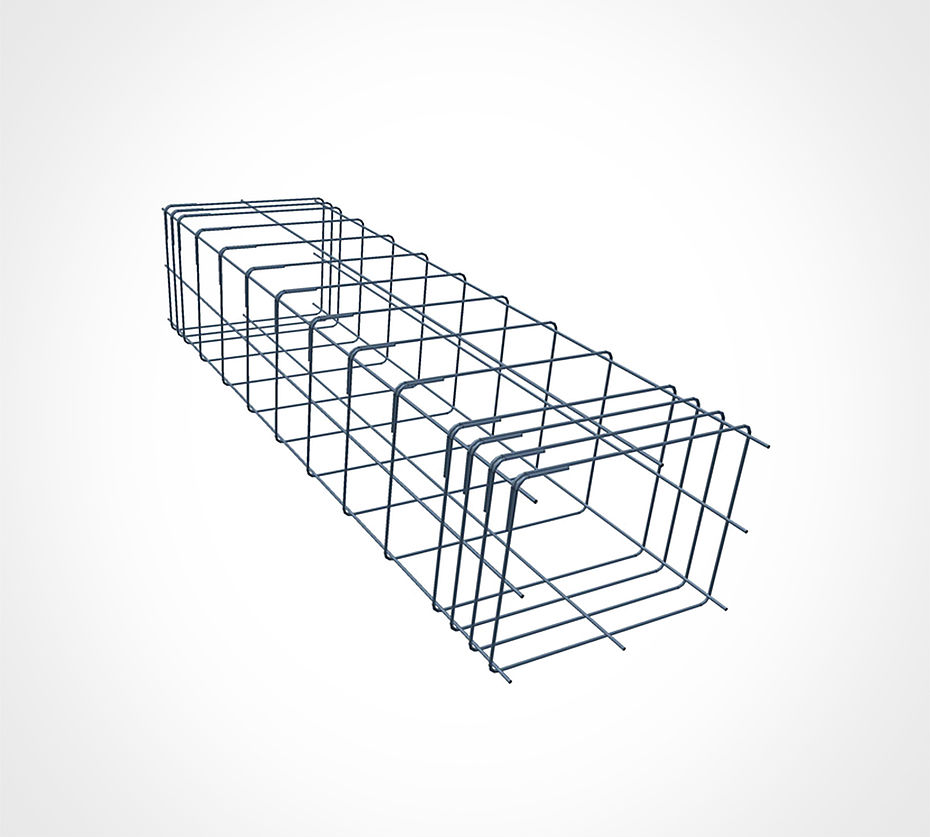

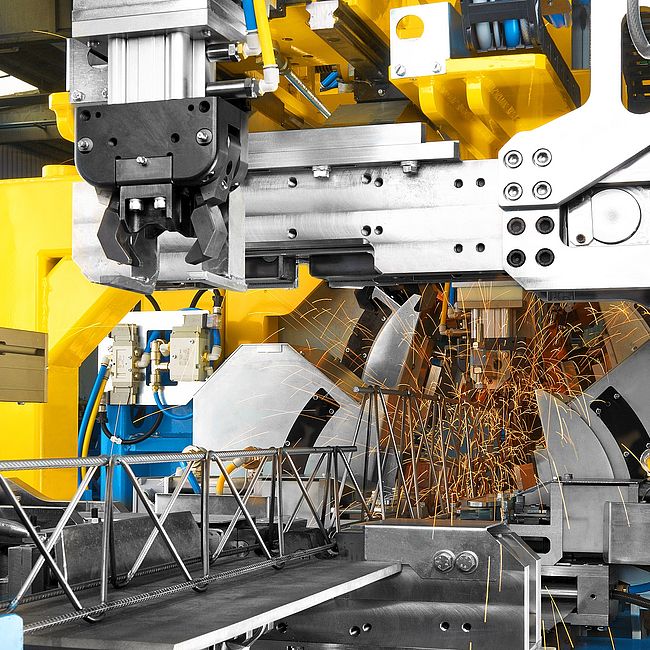

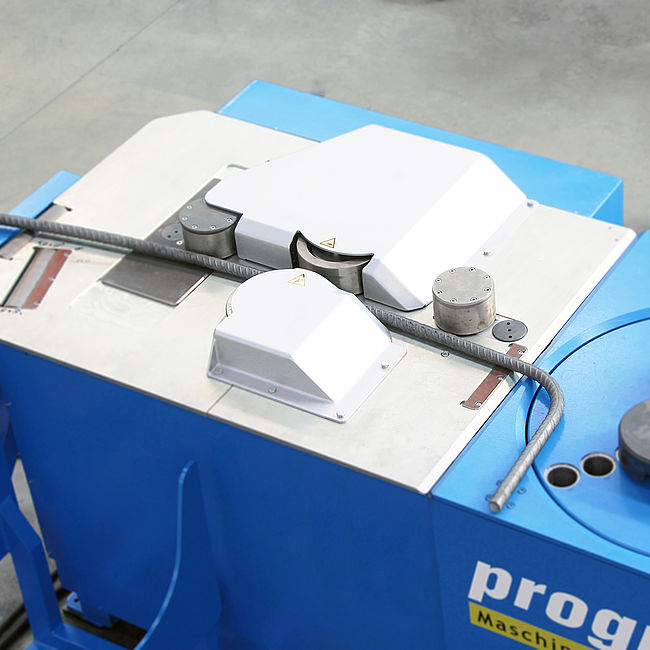

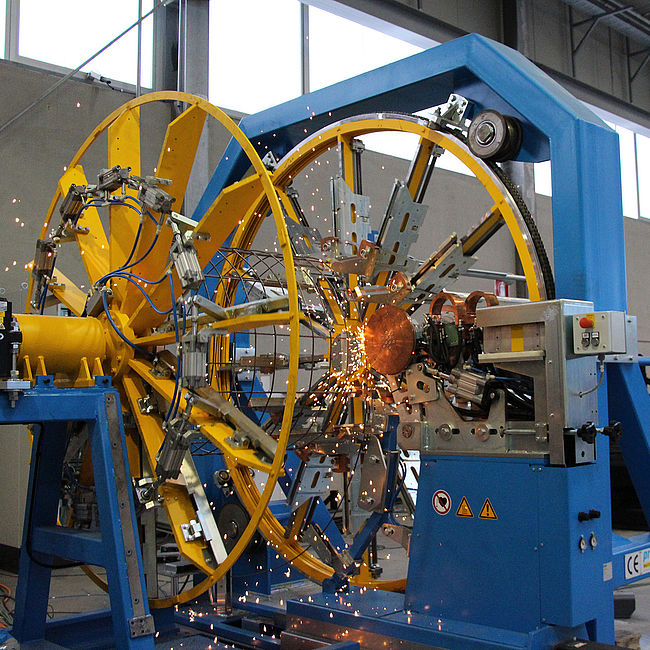

Bending systems

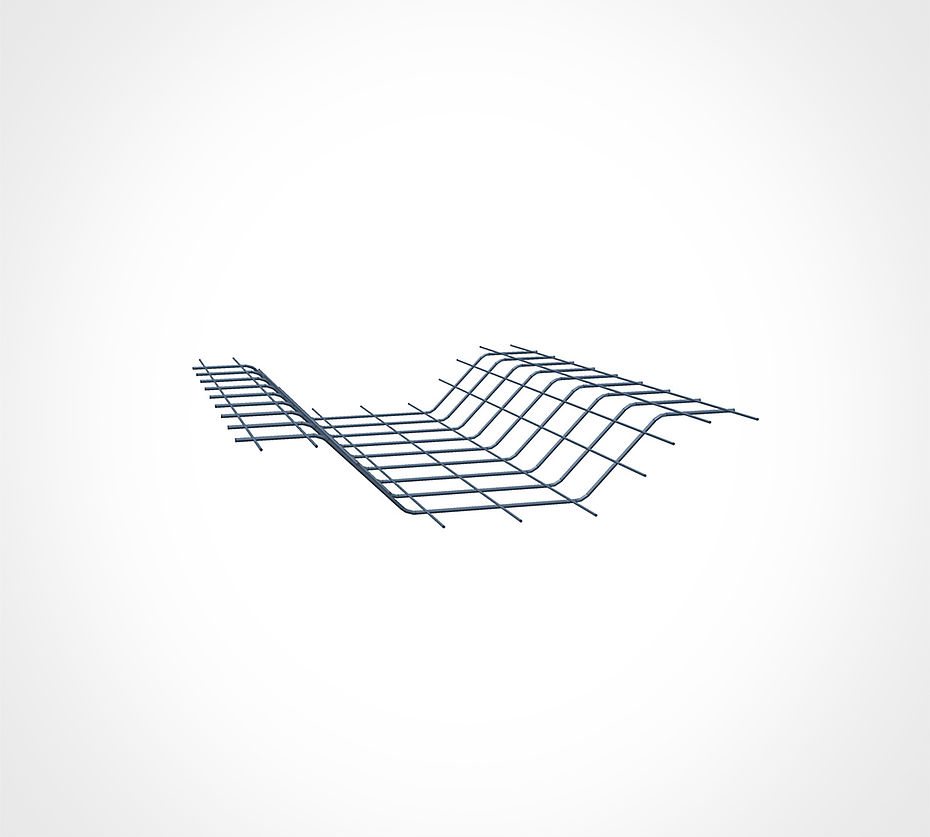

The BGM bending machine is designed for the fully automatic bending of individual bespoke mesh. The machine can be equipped with a beam or individual bending device. In combination with the gridless production of mesh, the beam bending system allows the totally accurate production of cages with iron in the corners of the cage. Fully automatic bending of individual rebar is also possible for window and door slots. Entire plant concepts and flexible transport and logistics systems complete this solution.

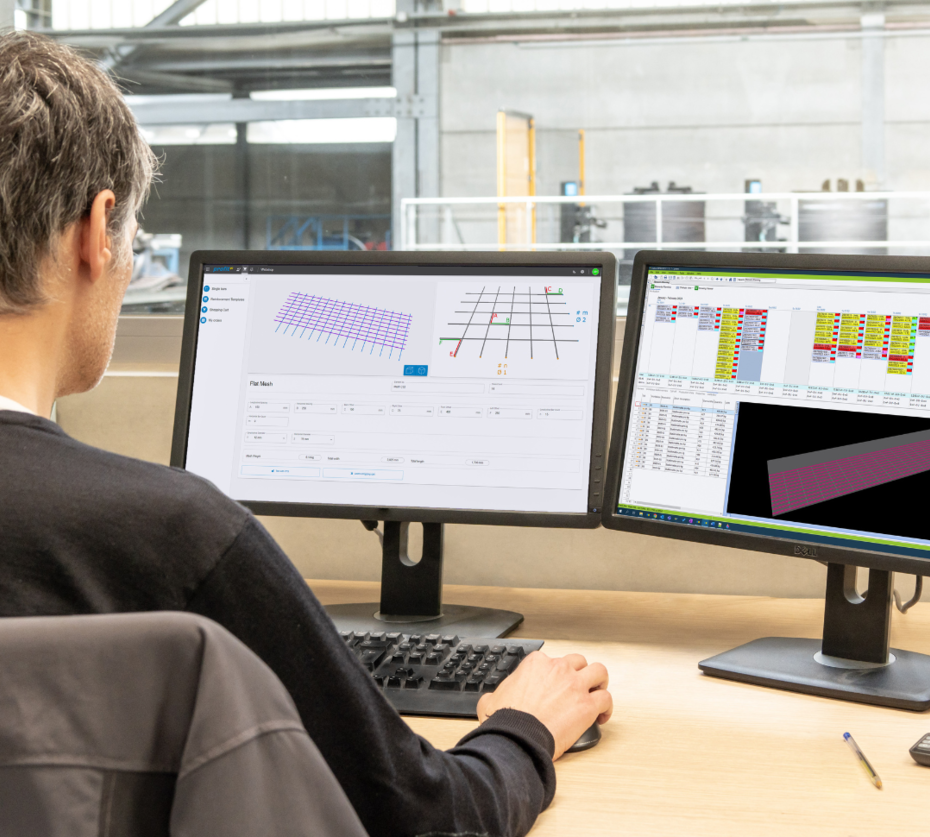

The ideal software package for mesh welding plants

Achieve an optimized model-based workflow with Model2Fabrication, an Autodesk Revit plug-in that streamlines the design phase. By converting data for automation and production, the software ensures a smooth and error-free process. During the planning phase, erpbos® provides an array of benefits, including transparent element status, and material overviews, as well as optimized capacity, production, and logistics planning based on real-time information. This helps keep costs and time under control. Lastly, during production, the MES-System profit for rebar processing oversees and governs all production processes and machines to ensure flawless and optimal results.

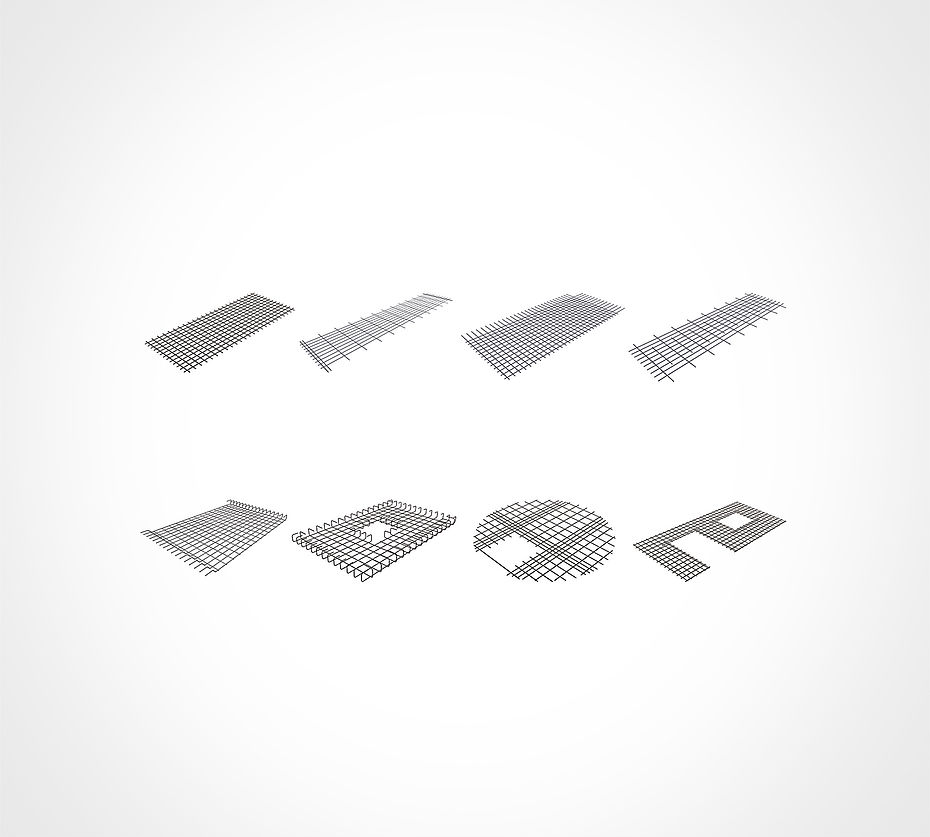

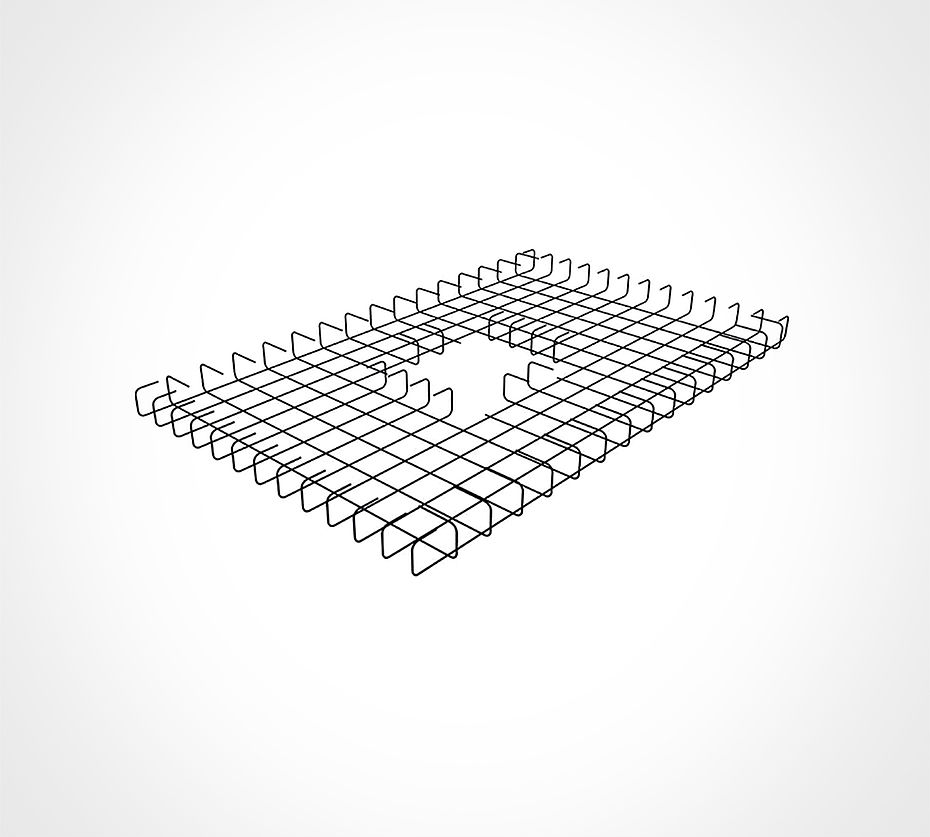

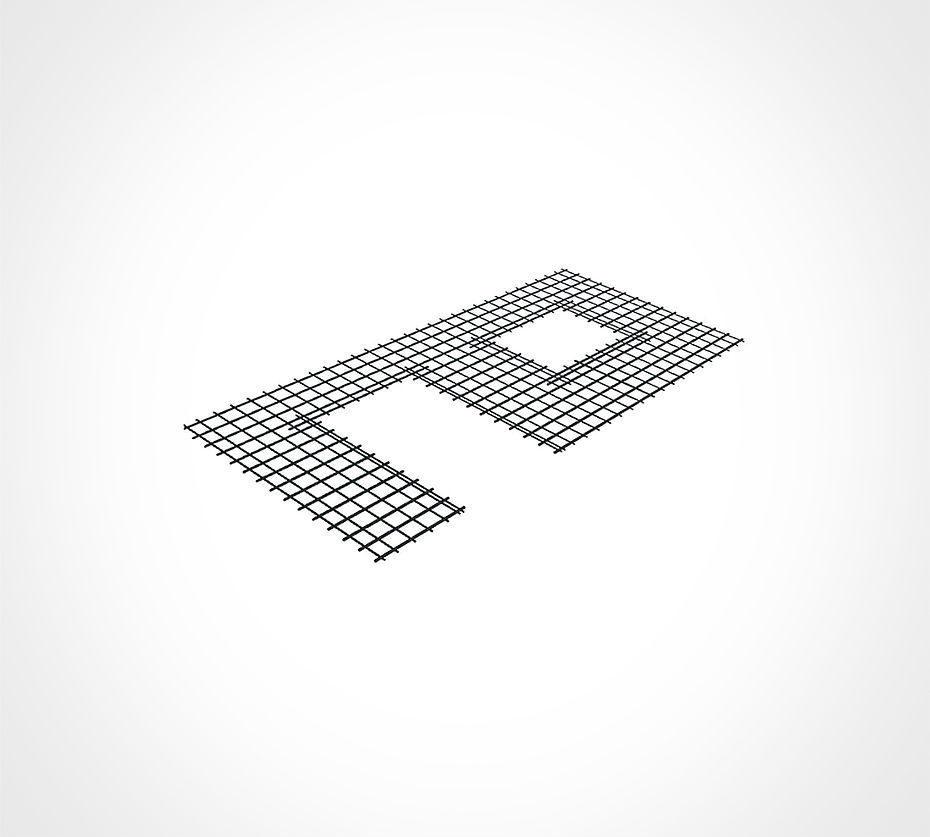

Bespoke Mesh

Bespoke mesh is used ad static reinforcement in the concrete element. For example, bespoke mesh is used in two-dimensional precast concrete elements, such as wall and ceiling elements. A distinction is made between predominantly static and non-static effects in welded mesh.

Bent bespoke mesh and cages are manufactured from mesh, which is bent after production of the mesh. The mesh is either welded together or intertwined (fastened). It is used, for instance, for pillars, columns, girders, pipe installation and for connections between walls.