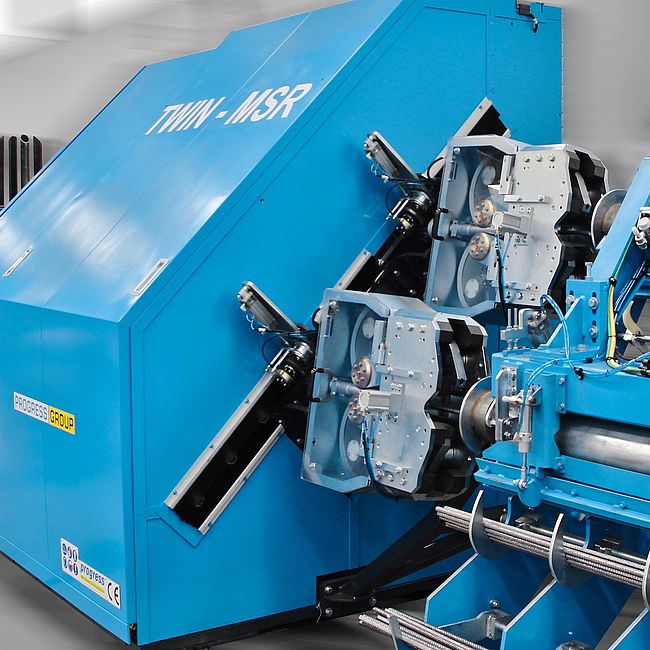

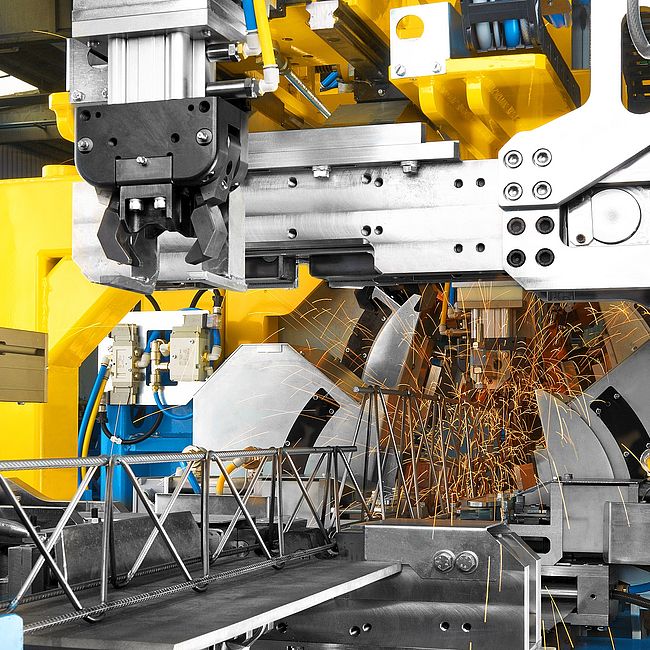

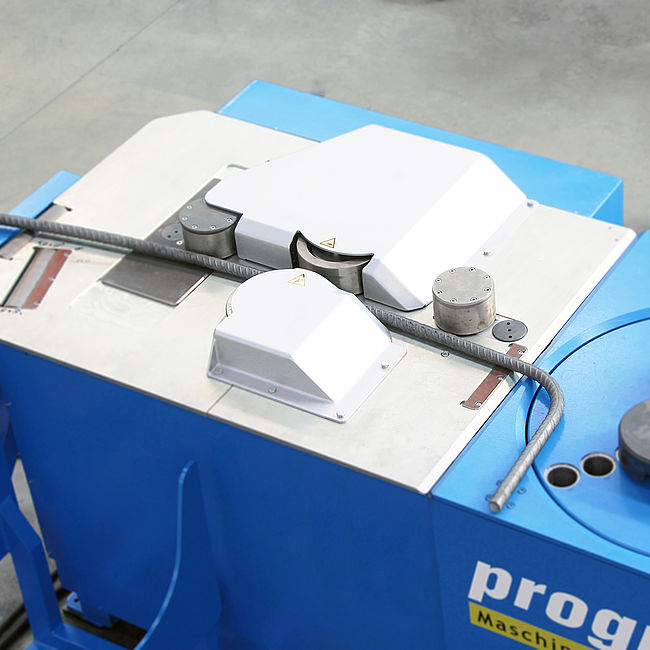

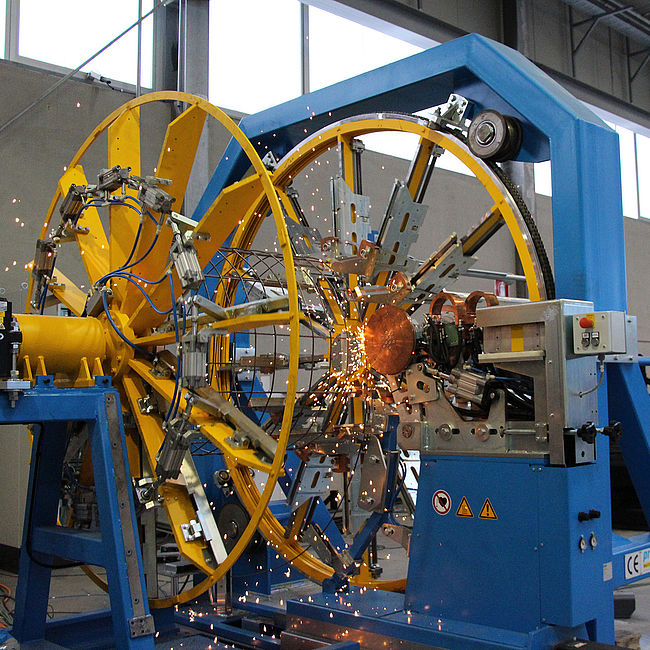

Automatic stirrup benders

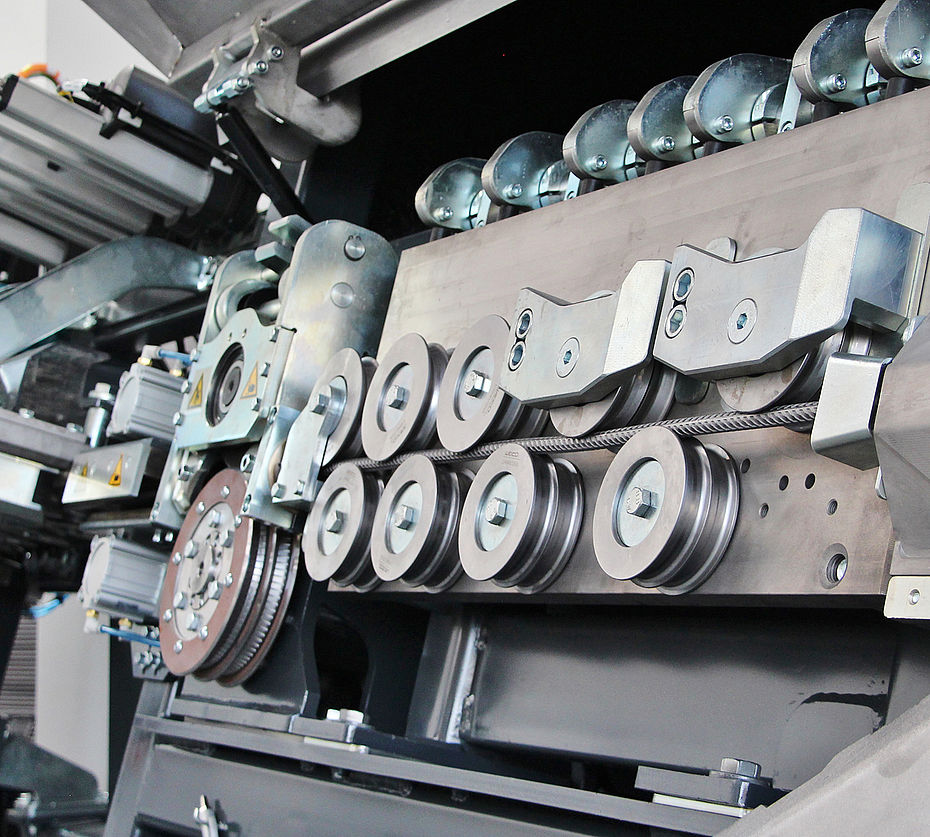

EBA-Line automatic stirrup benders are sturdy, compact and high-performance. A system for quick wire changeover and automatic changeover from processing of double strand to single strand and the automatic setting of the straightening rate ensure high productivity, while the robust bending system ensures precision. A 3D bending system for manufacturing three-dimensional stirrups is also available. If the EBA is combined with a run-off, production with or without bending becomes possible.

Flexible and adjustable to customer requirements

A wide range of production possibilities

EBA series

EBA-Line automatic stirrup benders are easy to operate and feature integrated, high-quality control allowing extremely high performance and precision.

Technical data

| EBA 12 | EBA 14 | EBA 16 | EBA 16 Plus | EBA 20 | |

| Diameter range single wire | 5 - 12 mm (#4) | 5 - 14 mm (#4) | 5 - 16 mm (#5) | 5 - 16 mm (#5) | 10 - 20 mm (#6) |

| Diameter range double wire | 6 - 10 mm (#3) | 6 - 10 mm (#3) | 6 - 12 mm (#4) | 6 - 12 mm (#4) | 10 - 16 mm (#5) |

| Max. feed rate | 160 m/min. (525 ft/min.) | 160 m/min. (525 ft/min.) | 160 m/min. (525 ft/min.) | 160 m/min. (525 ft/min.) | 140 m/min. (460 ft/min.) |

| Power unit | Electric servo-drive (no hydraulics) | Electric servo-drive (no hydraulics) | Electric servo-drive (no hydraulics) | Electric servo-drive (no hydraulics) | Electric servo-drive (no hydraulics) |

| Automatic change of wire diameter | optional | optional | optional | optional | inclusive |

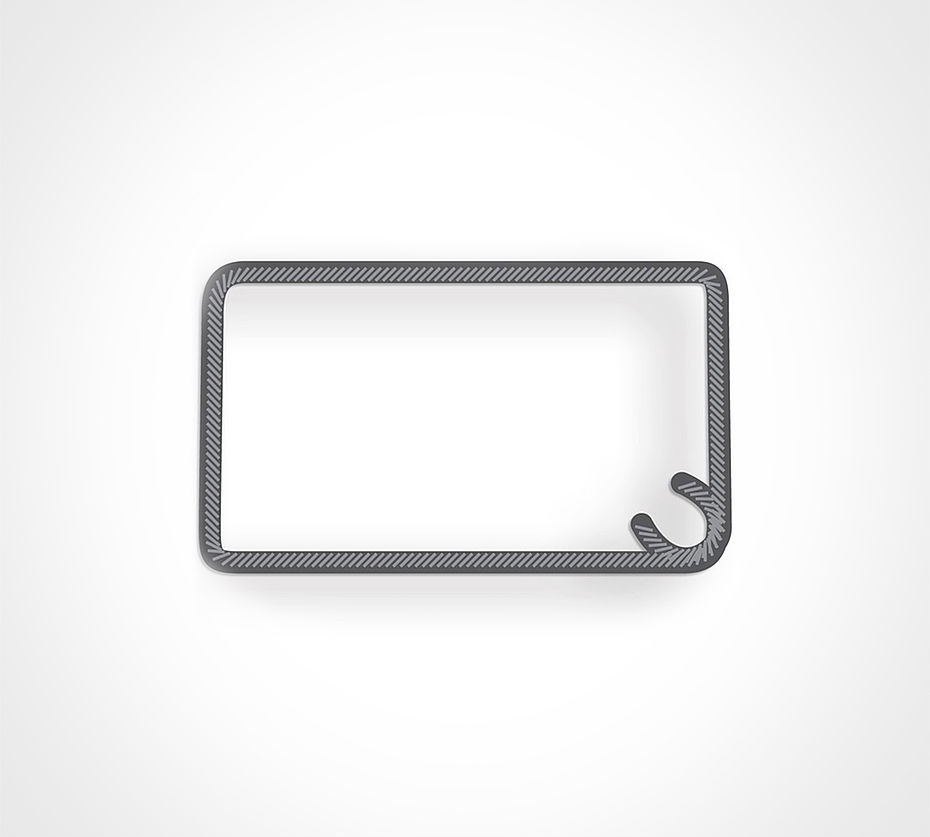

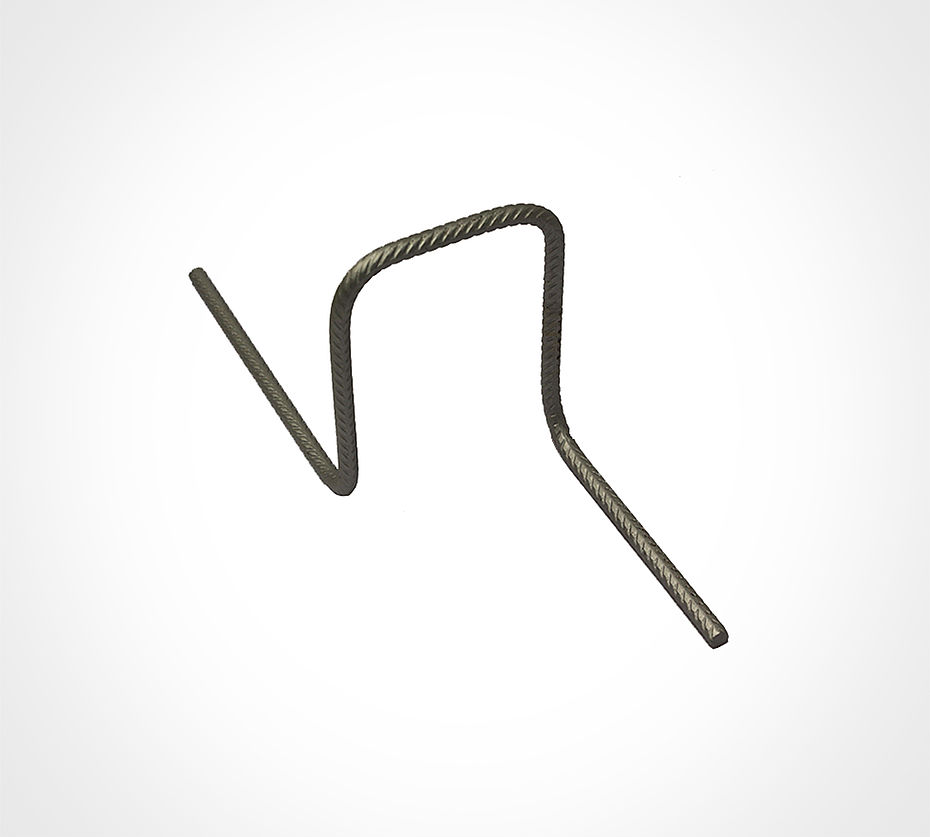

Stirrups

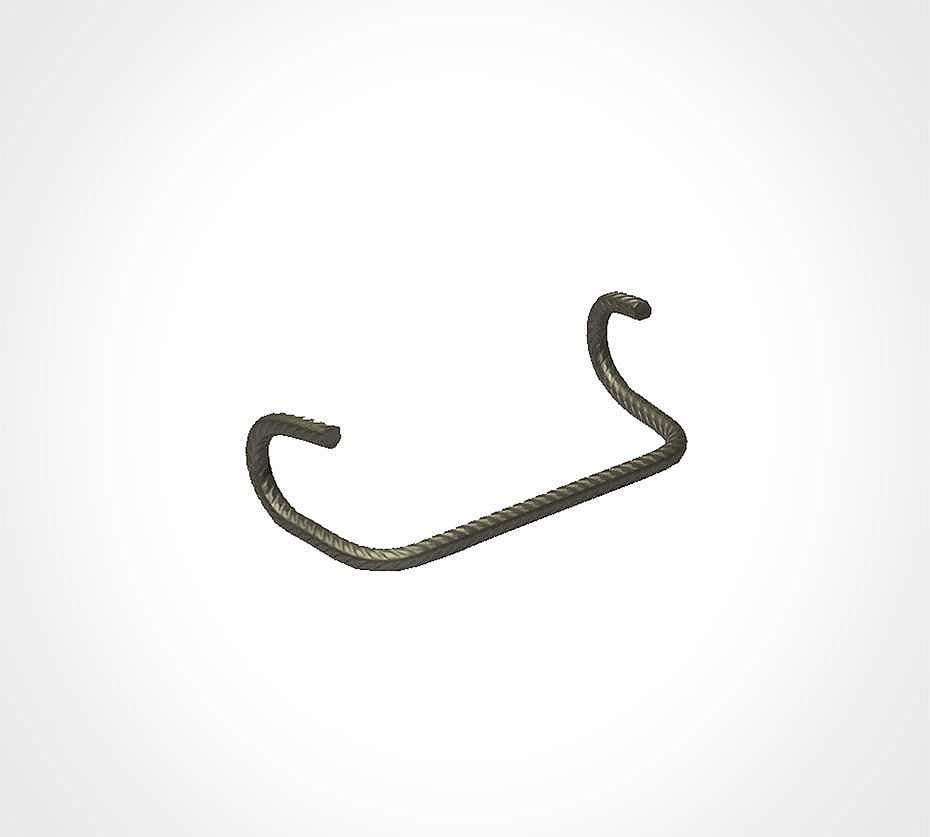

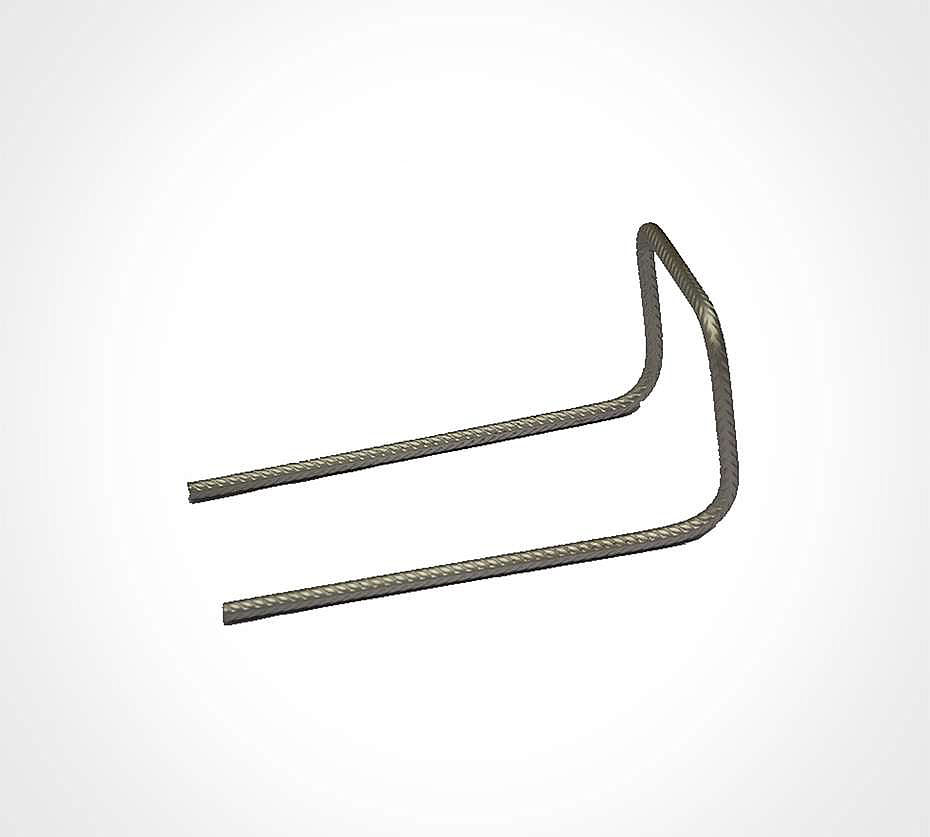

Reinforced steel stirrups come in many shapes: bent on one side or on several sides, 3D, closed or open. Rebar stirrups can be subsequently processed in an intertwining or fastening process or welded into mesh and cages.

Stirrups are used as spacers between wall and ceiling elements, in the connection between two walls and in pillars, girders, strip foundations or lintels. They are decisive for the statical properties of the precast concrete element.

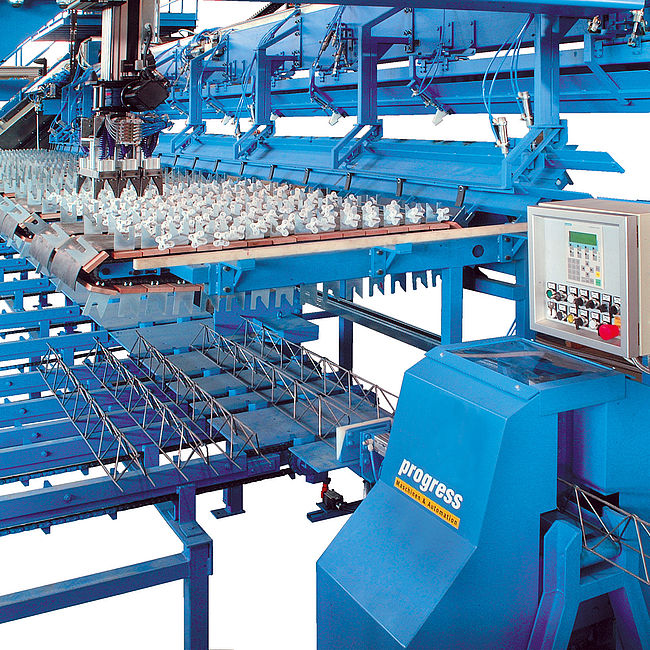

Pluristar

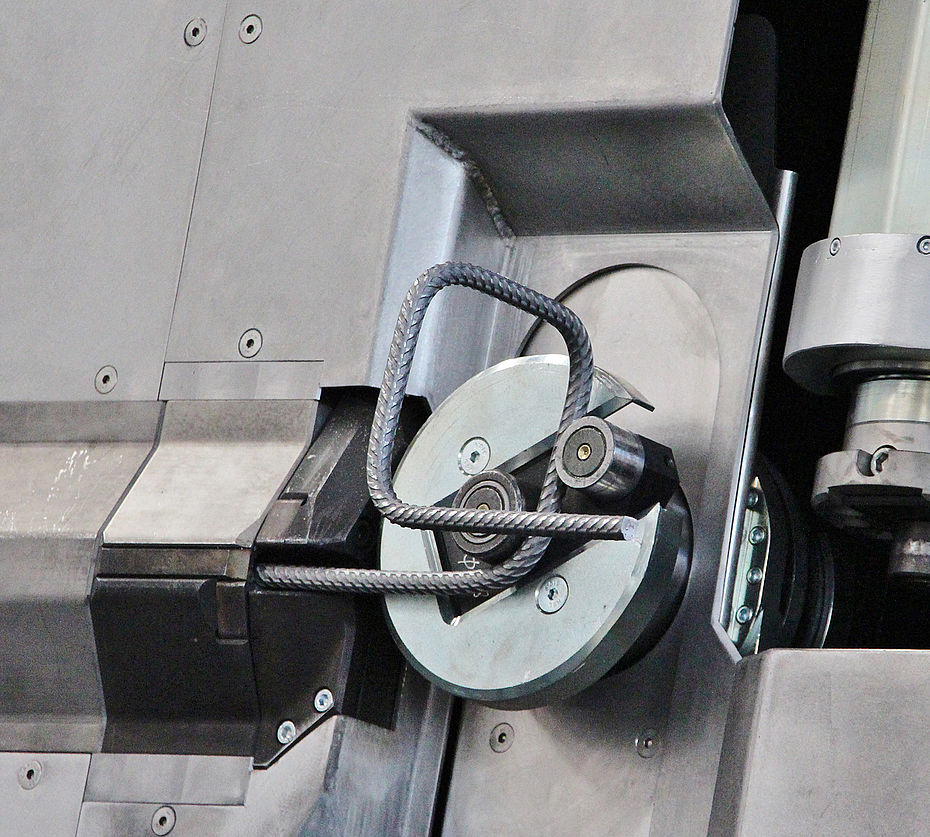

The Pluristar is an automatic stirrup bender, straightener, and double-bending machine in one. It can process wire diameters of 6 – 16 mm. The heart of the Pluristar is the combined straightening system consisting of a roller straightening unit and a rotor straightening unit. This unique combination allows the flexible manufacture of stirrups, straight rebars, and rebars with large bends using just a single machine. Depending upon the given product, the suitable straightening unit is inserted fully automatically. The wire is changed fully automatically or manually, as required. The Pluristar can also be equipped with a 3D bending system allowing not only 2-dimensional, but also 3-dimensional stirrups to be produced.

Technical features

| Wire processing | from coil |

|---|---|

| Wire diameters | 6 - 16 mm |

| Wire diameter changeover | fully automatic |

| Drive type | electric servo-drive (no hydraulics) |

| Max. feeding rate | 160 m/min. |

| Data input | keyboard / network / USB / bar code |

| Production options | stirrup mode or rotor mode |

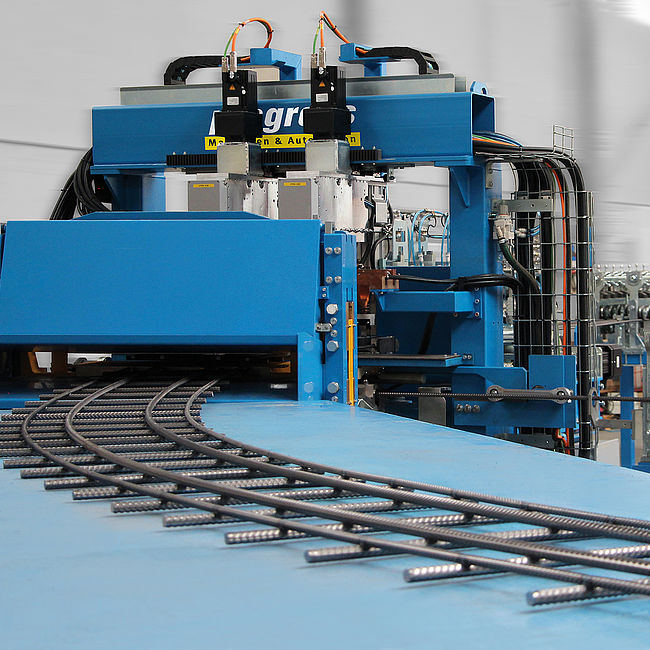

Run-off process

| Run-off models | 2BK-16 | ETI | OT |

|---|---|---|---|

| Single-strand diameters | 6 - 16 mm | 6 - 16 mm | 6 - 16 mm |

| Double-strand diameters | 6 - 12 mm | 6 - 12 mm | / |

| Central clamping unit | Yes | No | No |

| Automatic bending diameter | optional | optional | / |

| Producer countries | customised | customised | customised |

| Bending angle | +180°C/-180° | +180°C/-90° | +180°/-90°, z-shaped |

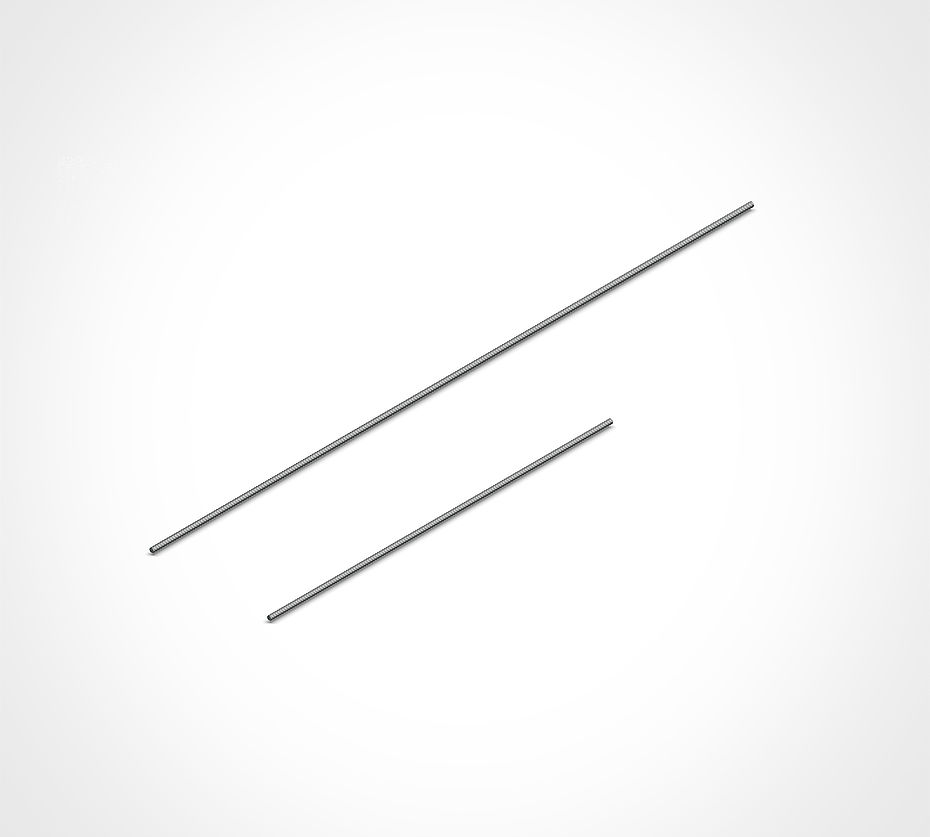

Bars

Steel bar or mesh is used to produce reinforcement for precast concrete elements. The bars have a ribbed surface, which ensures optimum interlinking with the concrete. Reinforcement bars are processed either as bar material or direct from the coil. Bars can be linked together into cages or mesh either by a weaving process with linking material (fastening) or by being welded. They can be straight, or bent single-sided or multi-sided.