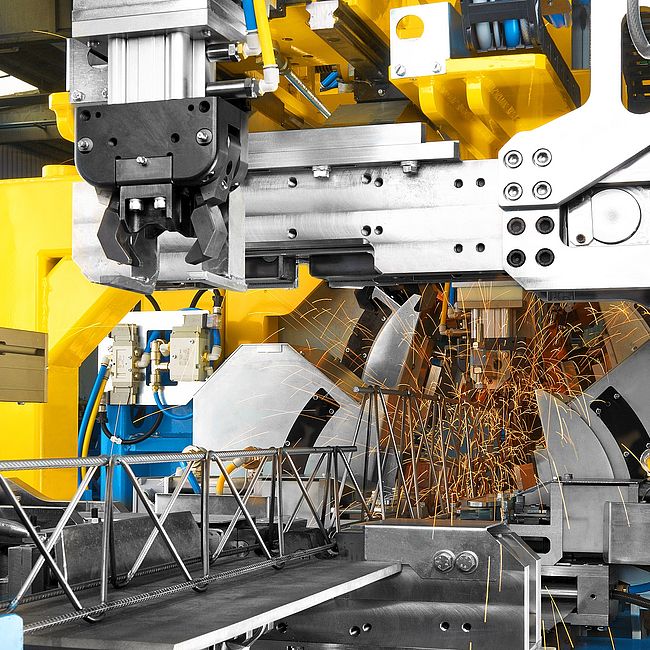

Special machines

We have specialised in creating tailor-made solutions. We are happy to develop new plant concepts and solution and to provide advice and development. We work with you to develop your ideal system for your rebar shop, your precast concrete plant or construction company. Together with our affiliated companies we provide complete turnkey solutions from one source.

Our machines facilitate the industrial production in conformity with standards of made to measure mesh elements e.g. stirrup cages and column reinforcements on the basis of CAD data. The made to measure mesh elements can be delivered finished to the construction site and are ideal for beams, columns and pillars. In this way production costs are reduced, optimum quality and product safety are guaranteed and work on the construction site is reduced.

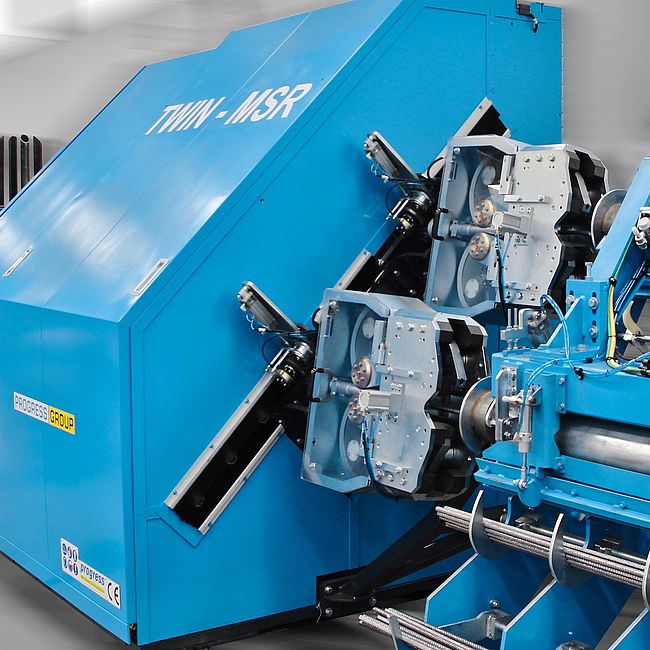

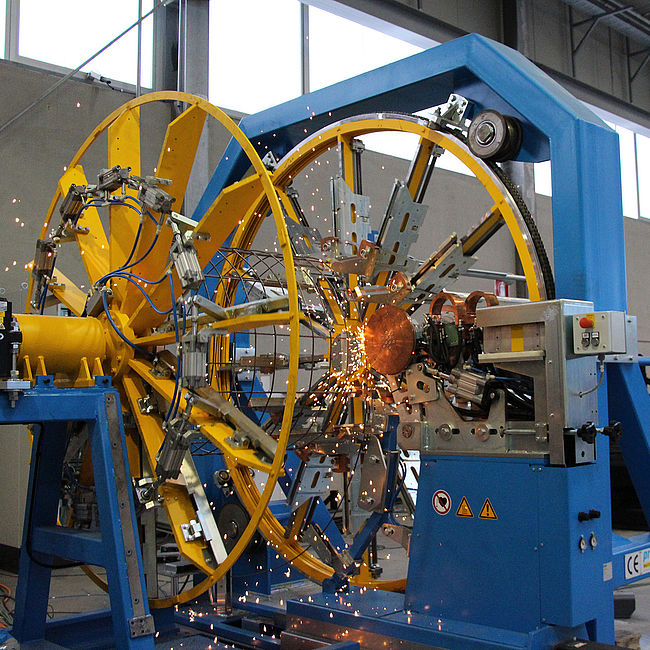

Smart BGM

This innovative system is flexible and precise. The Smart BGM comprises two independently operated bending machines, which facilitates the fully automatic bending of bespoke mesh. There is a versatile variety of shapes and bending angles. Squares, rectangles and triangles, as well as open shapes with angles from 90°to 135° can be manufactured. Depending on the mesh, various cage sizes with a variety of wire diameters can be produced. The number of stacked cages can be determined according to need. The Smart BGM is therefore ideal for the fully automatic series production of storage cages.

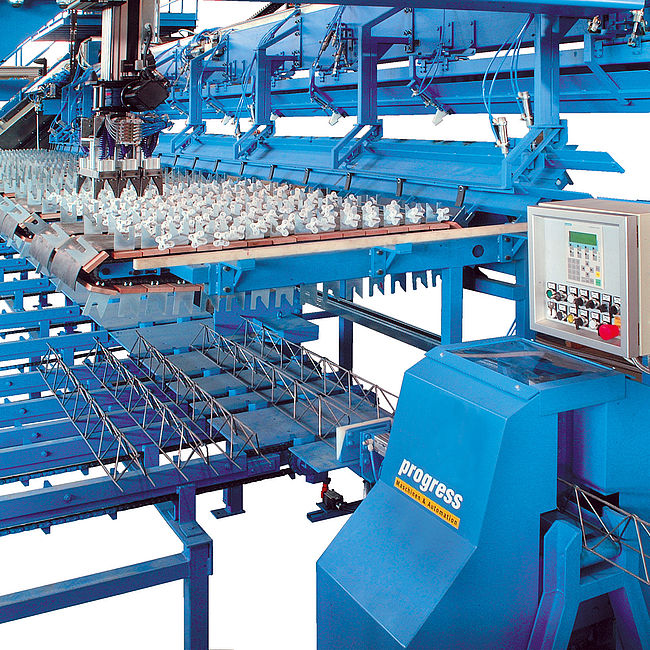

Mesh Spacer

The spacers for wire mesh mats were previously placed manually in the form of rings, plastics strips, or spacer bars. With the aid of a special solution, the Mesh Spacer, these elements can be replaced by special spacers and positioned on a production pallet fully automatically by a robot system. During production, a positioner takes the required number of spacers from the magazine and places them on the positions defined by the CAD-CAM data. The optimal position is calculated with the system’s own algorithm and monitored by an integrated laser system. In this way, uniform concrete cover can be ensured.

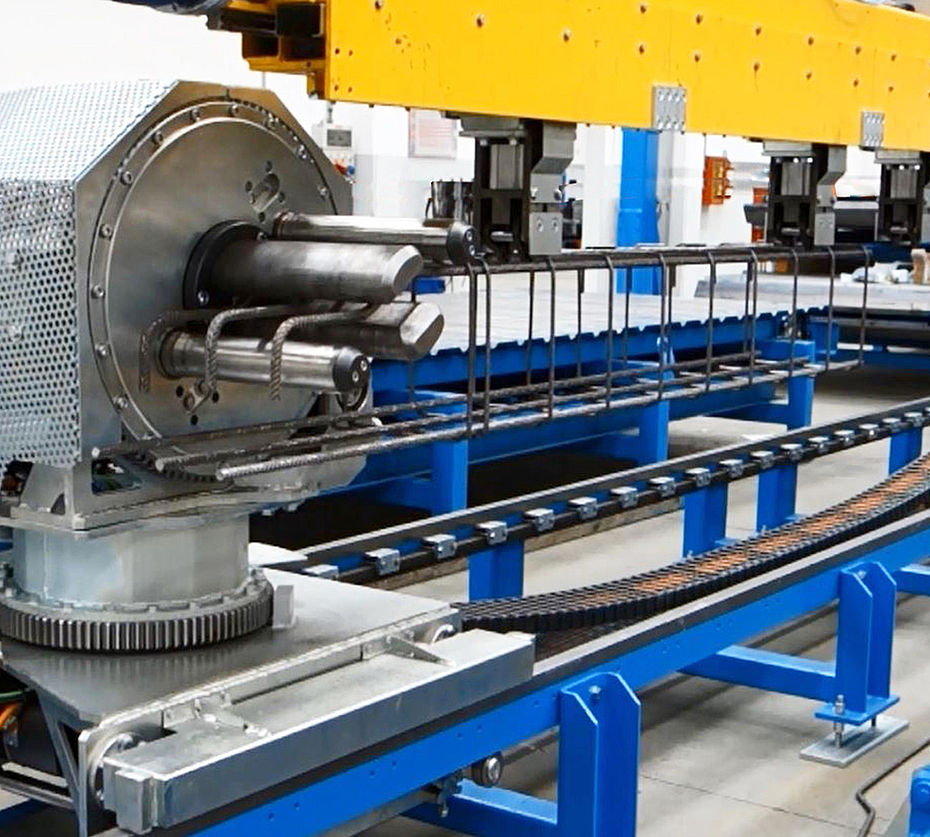

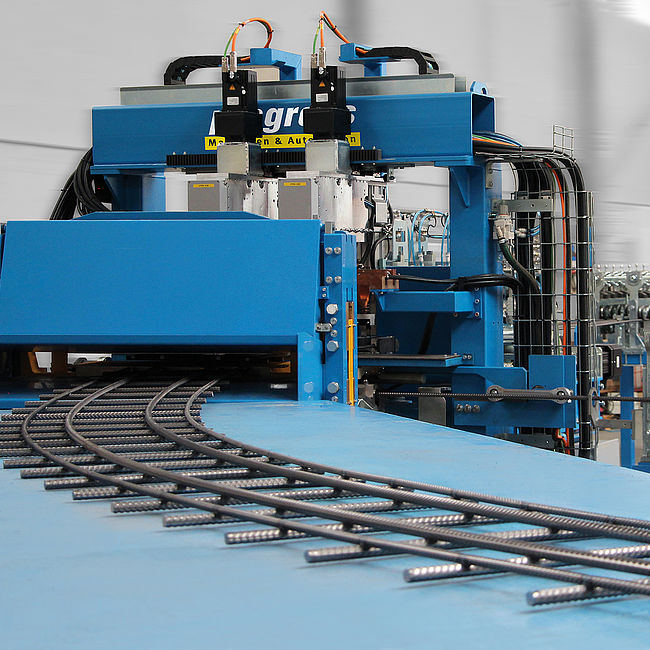

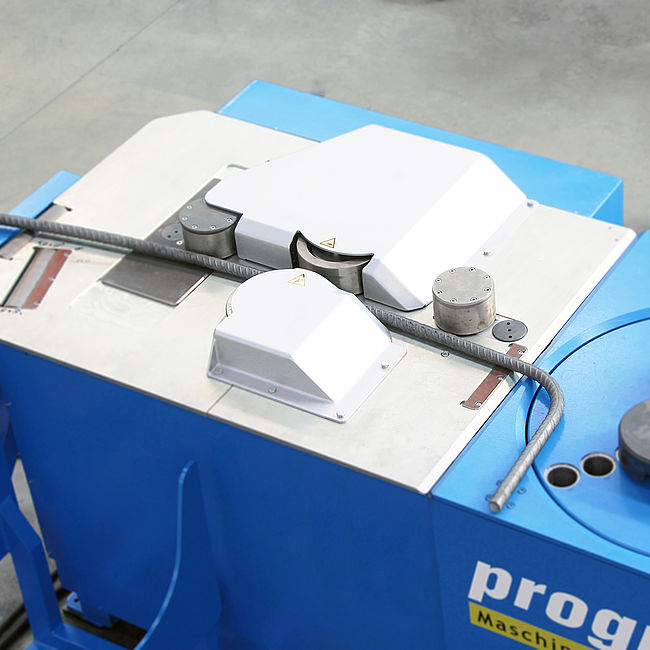

BAMTEC Evolution

The BAMTEC Evolution from progress is a fully automatic production system for the manufacture of BAMTEC made to measure mesh elements. It comprises a straightening and cutting unit for the fully automatic production of bar from the coil, together with a welding unit, which welds the straightened bars to a BAMTEC made to measure mesh element. Immediately after welding, the BAMTEC element is rolled on to a roller unit. The low number of made to measure mesh elements and the rapid roll-out speeds up and simplifies the installation on the construction site.