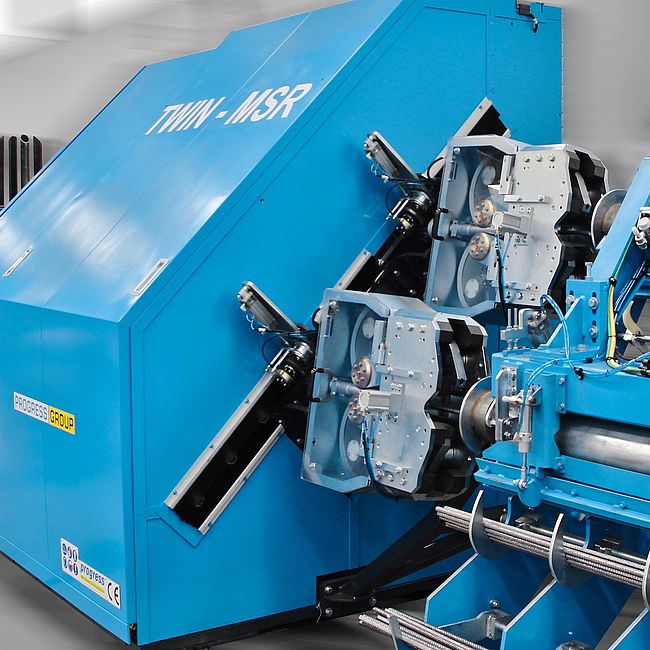

Cage welding machines

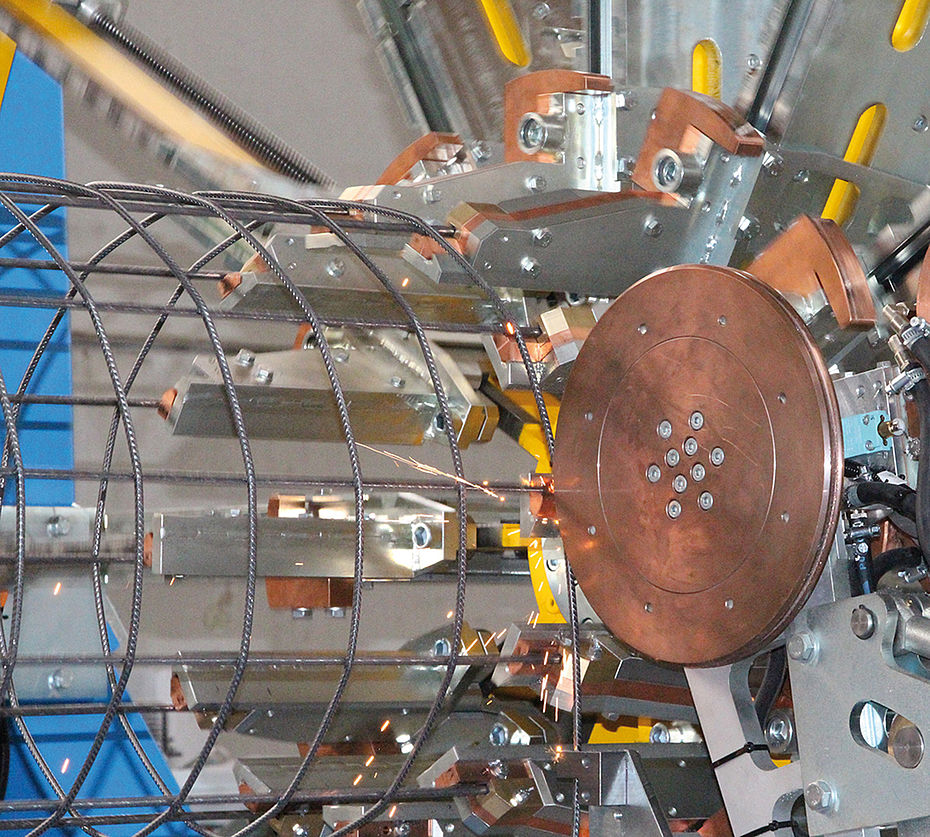

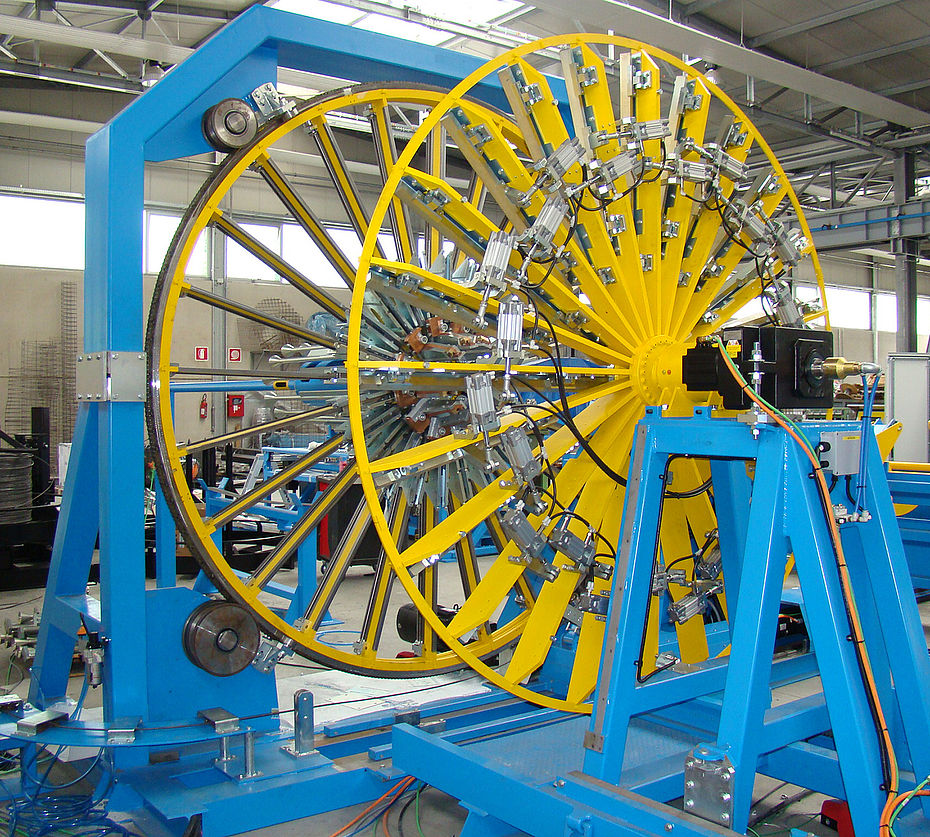

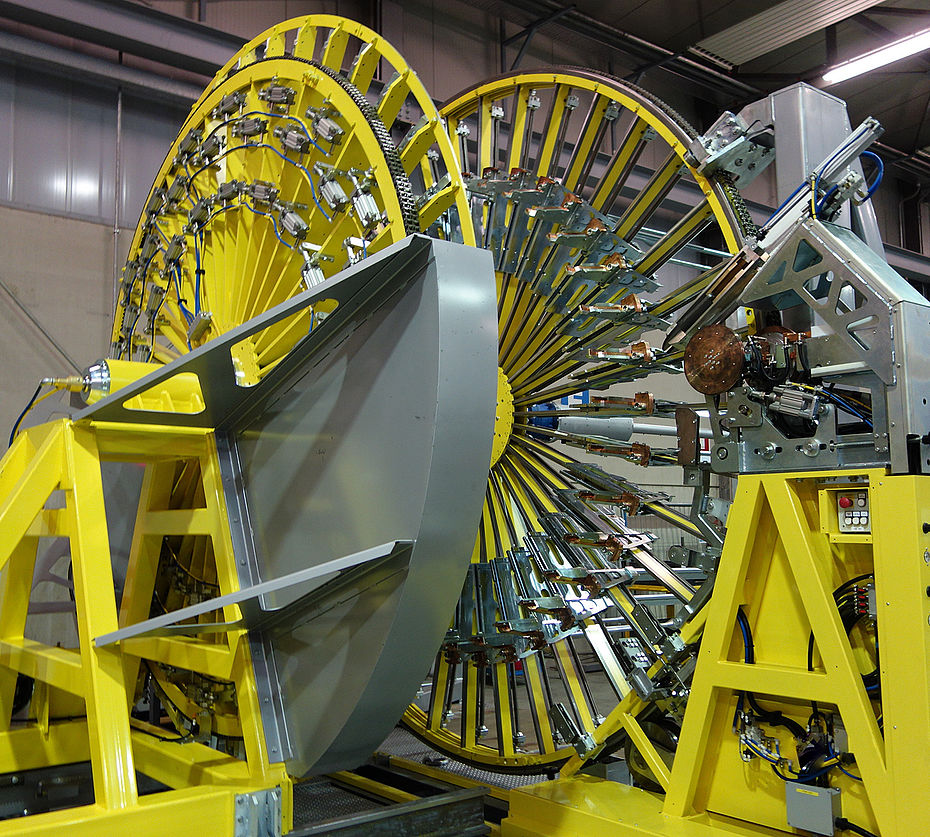

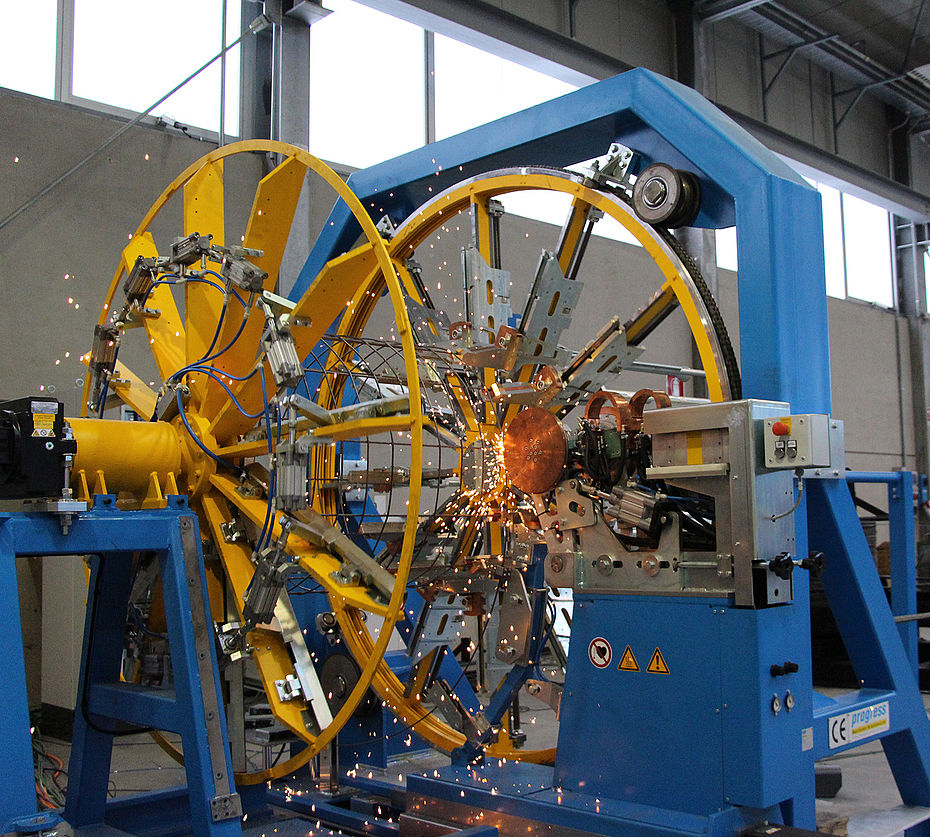

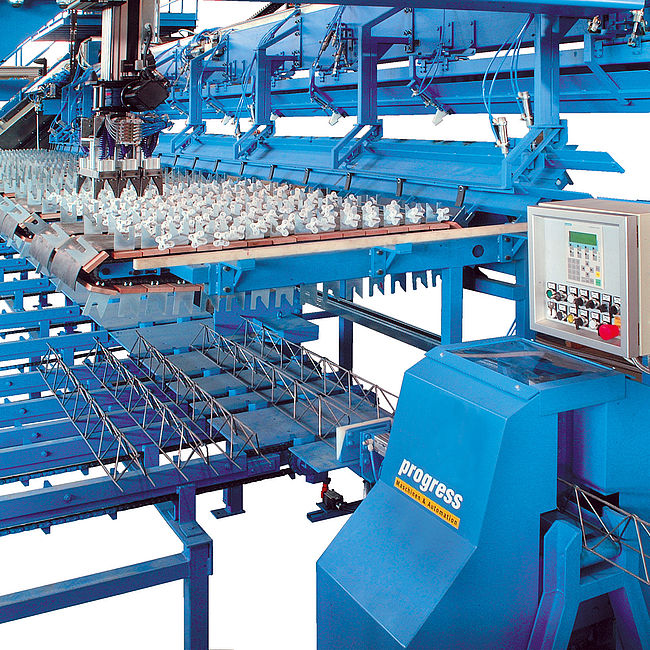

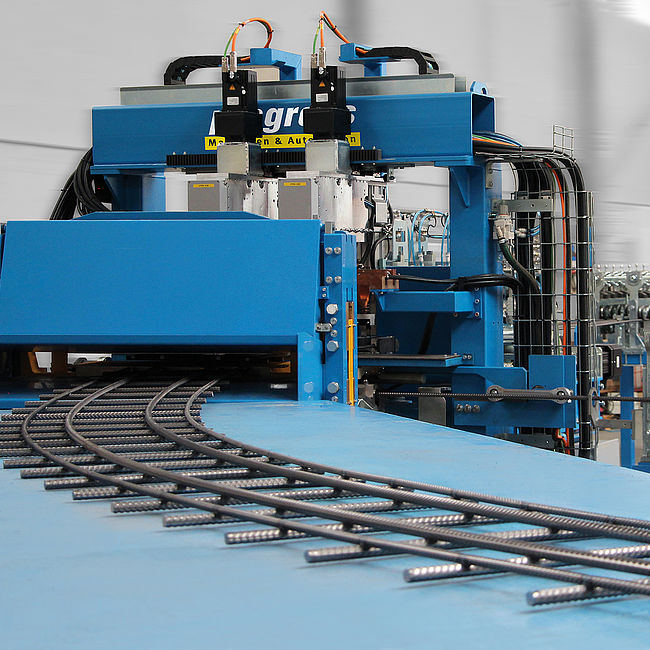

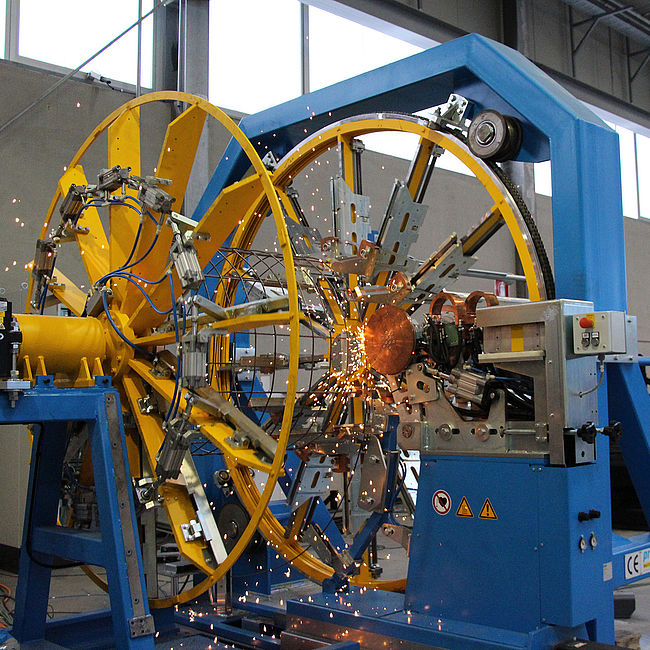

VTA series cage welding machines are used to manufacture cylindrical and where required, oval or rectangular cages. This machine has many configuration options. The longitudinal bars can be fed manually or automatically from rebar. Alternatively, processing from the coil in conjunction with a progress rotor straightening machine is possible. The inverter welding unit, an automatic winding wire cutter and automatic cage removal ensure efficient, accurate production processes and ease of operation.

The cage welding machines are available with several levels of automation:

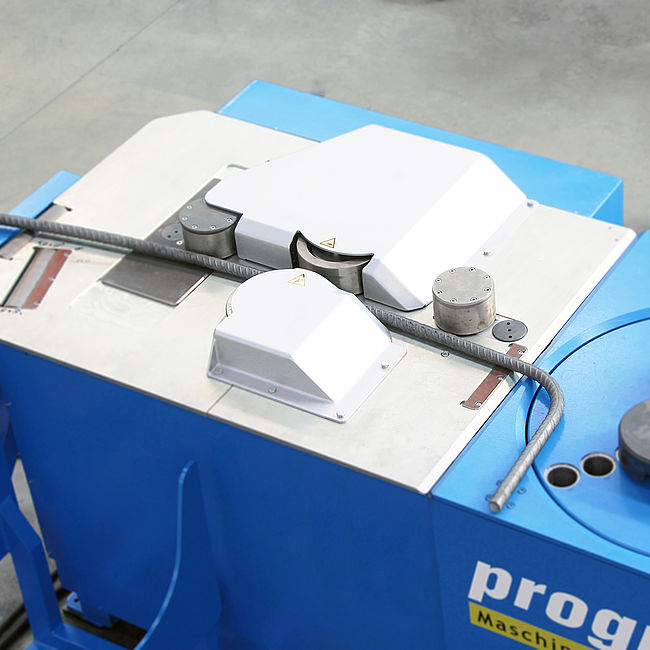

- Automatic straightening and cutting of longitudinal wires with rotor straightening machines

- The automatic feeding unit loads the machine with the longitudinal wires

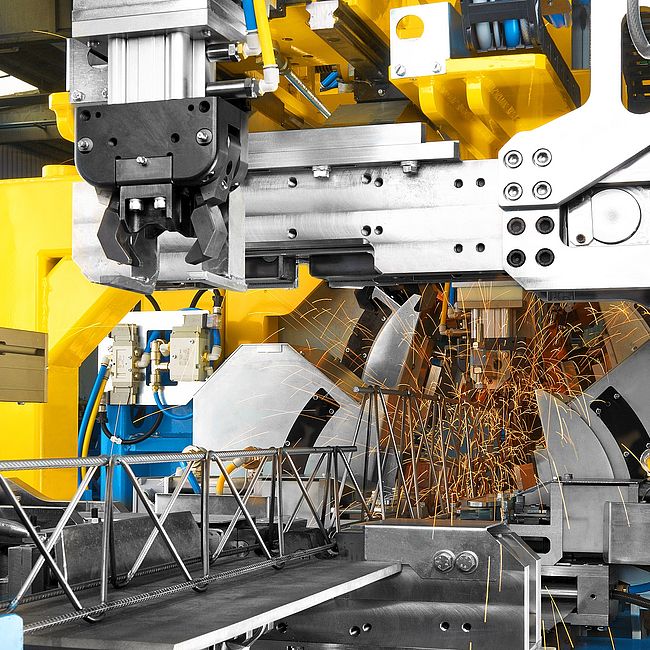

- The inverter welding unit ensures clean, accurate welding.

- The automatic winding wire cutter completes the cage production by cutting the winding wire automatically

- The fully automatic cage removal cart removes the cage and positions it

Versatility of configuration options

Various degrees of automation

Low wear and maintenance costs

Technical data

| VTA 160 | VTA 200 | VTA 250 | VTA 360 | |

| Diameter range | 300 - 1.600 mm | 300 - 2.000 mm | 320 - 2.500 mm | 820 - 3.600 mm |

| Standard length | 3.150 mm | 3.150 mm | 3.150 mm | 3.150 mm |

| Number of length irons | 6 - 12 | 6 - 12 | 6 - 24 | 6 - 36 |

| Diameter length irons | 4 -8/ 10 mm | 4 - 8/ 10 mm | 4 - 8/ 10 mm | 4 - 8/ 10 mm |

| Gradient winding wire | 20 - 160 mm | 20 - 160 mm | 20 - 160 mm | 20 - 160 mm |

| Diameter winding wire | 4 - 10 mm | 4 - 10 mm | 4 - 12 mm | 4 - 12 mm |