Straightening and cutting machines

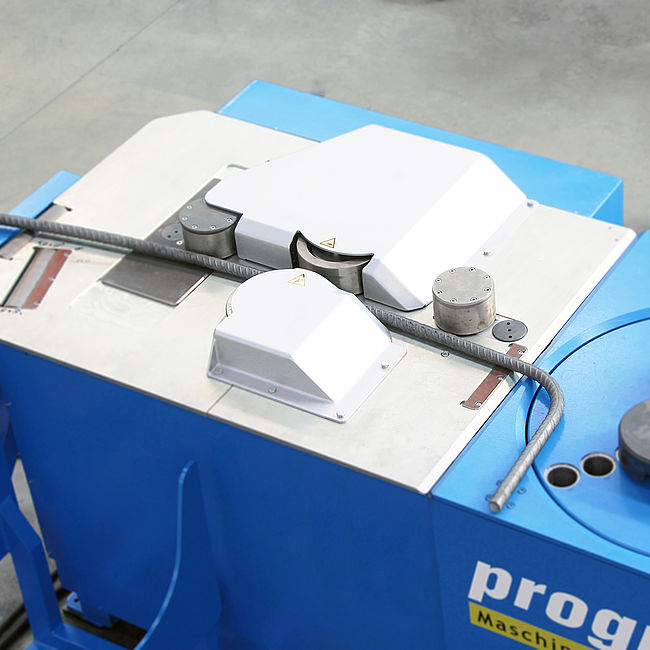

When straightening wires, the aim is to achieve consistent results even when using very different qualities of steel. Our rotor straightening technology is a guarantee of optimum processing and conformity with applicable norms. We offer a wide range of application-specific systems for efficient material handling. Our rotor straightening machines satisfy optimum conditions for every specific production requirement, because we constantly upgrade them and construct individualised components to make them available at different levels of automation.

High production output

Tried and tested components mean an exceptional quality final product

Optional double bending system

ESR

The ESR series single-rotor straightening machines are equipped with a single rotor suited to the given wire diameter. This all-round machine was designed for use in factories which place a premium on flexible production while still maintaining high production output. Rotor straightening system, wire run-off and the appropriate logistics system are designed to customer specifications.

Technical data

| ESR E12 | ESR 16 | |

| Wire diameters | 5 - 12 mm (#4) | 6 - 16 mm (#5) |

| Max. feeding rate | 160 m/min (525 ft./min) | 160 m/min (525 ft./min) |

| Diameter changeover | manual | manual/automatic (optional) |

| Drive type | electric servo-drive (no hydraulics) | electric servo-drive (no hydraulics) |

| Automatic rotor adjustment - ARV | No | optional |

| Flying shears | optional | optional |

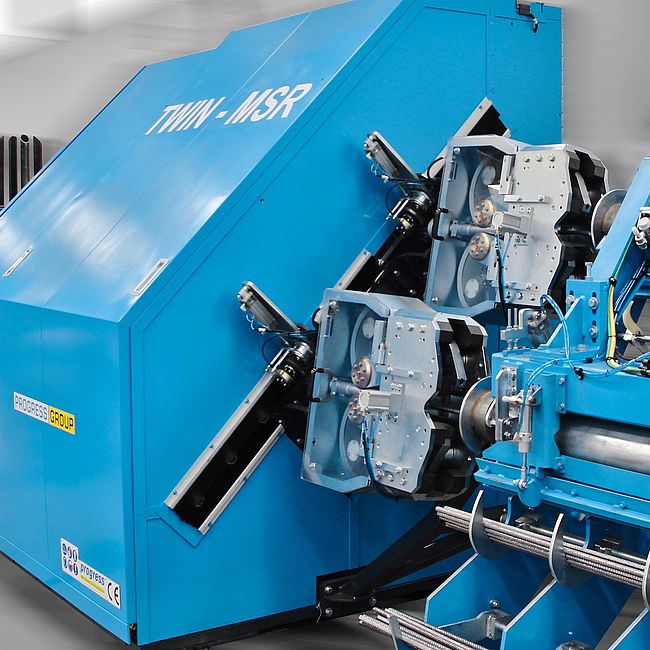

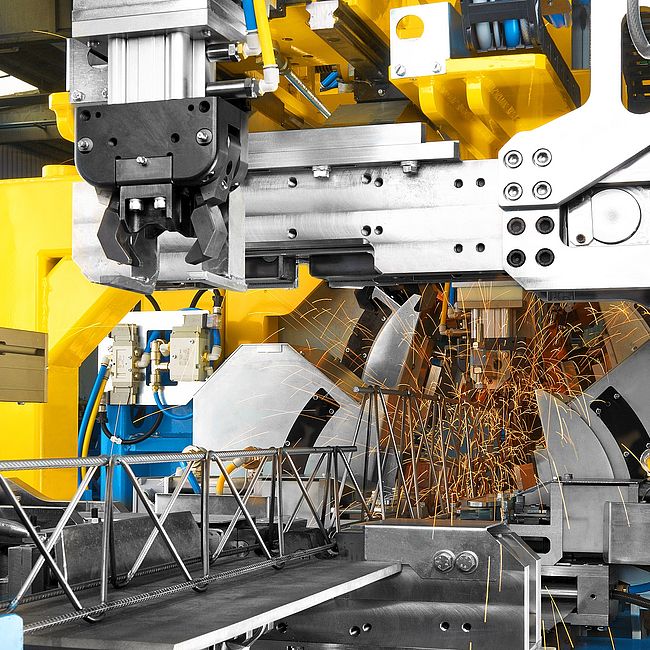

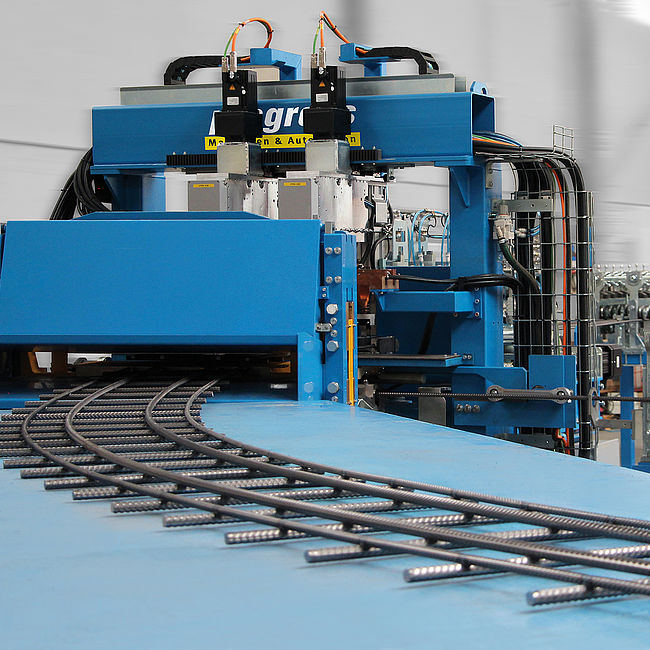

MSR & Twin MSR

The MSR and Twin MSR series straightening/cutting machines are high-performance machines for the production of fixed lengths. These rotor straightening machines are made for factories with high production demands.

Due to their various machine components, these systems make it possible to achieve high outputs. While the MSR produces one line per strand diameter, the Twin MSR is equipped with two rotors per diameter. Both types of machines are robust and characterised by high productivity and flexibility due to the extremely quick changing of strand diameters.

Technical data

| MSR 16 | MSR 20 | MSR 25 | Twin MSR 16 | Twin MSR 20 | |

| Wire diameters Single-strand processing | 6 - 16 mm (#5) | 8 - 20 mm (#6) | 12 - 25 mm (#8) | 6 - 16 mm (#5) | 8 - 20 mm (#6) |

| Number of rotors | up to 6 | up to 6 | up to 5 | up to 8 | up to 8 |

| Diameter changeover | fully automatic | fully automatic | fully automatic | fully automatic | fully automatic |

| Drive type | electric servo-drive (no hydraulics) | electric servo-drive (no hydraulics) | electric servo-drive (no hydraulics) | electric servo-drive (no hydraulics) | electric servo-drive (no hydraulics) |

| Production length | 8/10/12/14 m (others on request) | 8/10/12/14 m (others on request) | 8/10/12/14 m (others on request) | 8/10/12/14 m (others on request) | 8/10/12/14 m (others on request) |

| Max. feeding rate | 160 m/min. (525 ft./min) | 160 m/min. (525 ft./min) | 120 m/min. (395 ft./min) | 2 x 160 m/min. (525 ft./min) | 2 x 160 m/min. (525 ft./min) |

| Automatic rotor adjustment ARV | optional | optional | optional | optional | optional |

| Flying shears | optional | optional | optional | optional | optional |

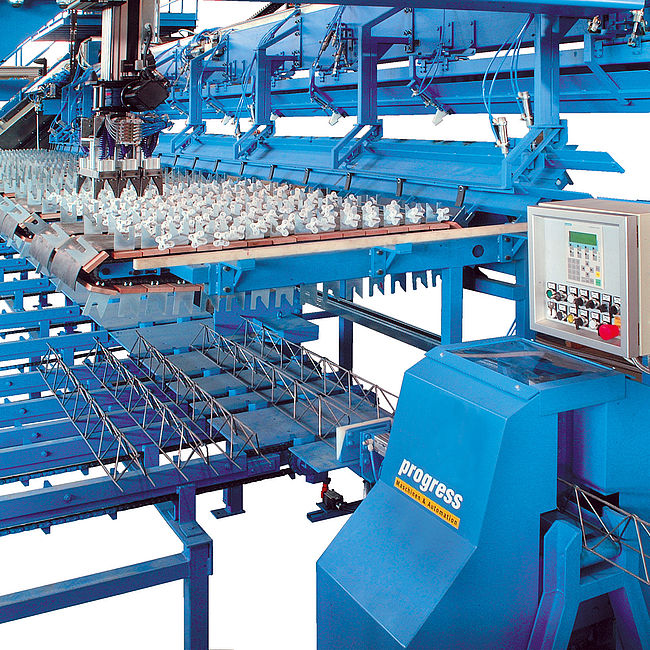

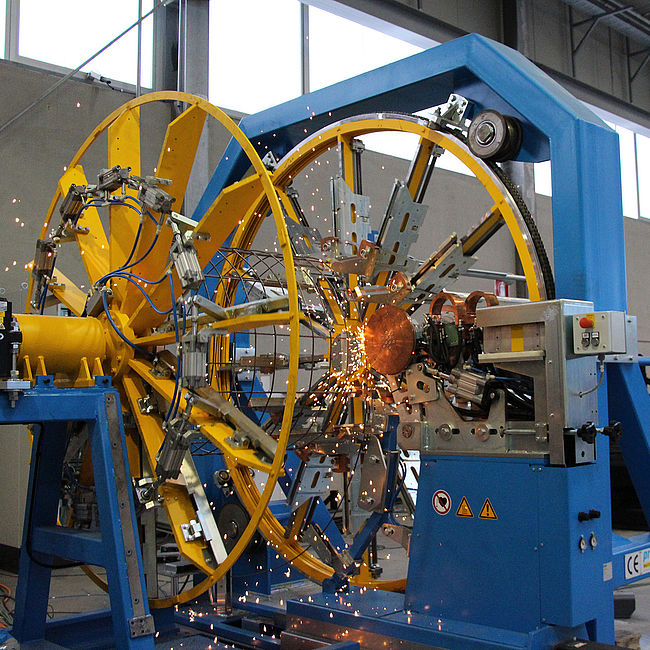

MMR & TWIN MMR

The MMR straightening/cutting machine features strand-feeding and cutting units for each rotor, which saves time when changing wire diameters. The Twin MMR makes possible double and simultaneous production. Each wire diameter is thus prepared for production. The MMR is especially well suited for use as an integral component of the welding machines for M-System series bespoke mesh.

Technical data

| MMR 16 | MMR 20 | Twin MMR 16 | Twin MMR 20 | |

| Wire diameters | 6 - 16 mm (#5) | 8 - 20 mm (#6) | 6 - 16 mm (#5) | 8 - 20 mm (#6) |

| Diameter changeover | fully automatic, no down time | fully automatic, no down time | fully automatic, no down time | fully automatic, no down time |

| Drive type | electric servo-drive (no hydraulics) | electric servo-drive (no hydraulics) | electric servo-drive (no hydraulics) | electric servo-drive (no hydraulics) |

| Number of rotors | up to 6 | up to 6 | up to 8 | up to 8 |

| Production length | 8/10/12/14 m (others on request) | 8/10/12/14 m (others on request) | 8/10/12/14 m (others on request) | 8/10/12/14 m (others on request) |

| Feeding rate | 140 m/min. (460 ft./min) | 140 m/min. (460 ft./min) | 2x 140 m/min. (460 ft./min) | 2x 140 m/min. (460 ft./min) |

Bars

Steel bar or mesh is used to produce reinforcement for precast concrete elements. The bars have a ribbed surface, which ensures optimum interlinking with the concrete. Reinforcement bars are processed either as bar material or direct from the coil. Bars can be linked together into cages or mesh either by a weaving process with linking material (fastening) or by being welded. They can be straight, or bent single-sided or multi-sided.