M-System BlueMesh

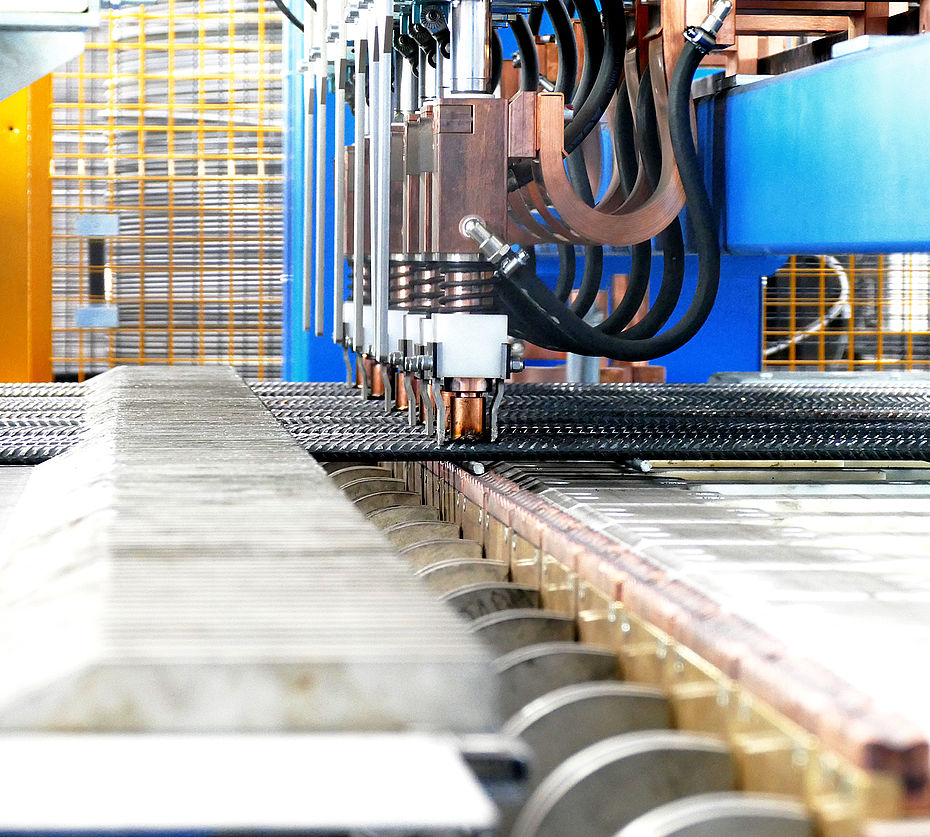

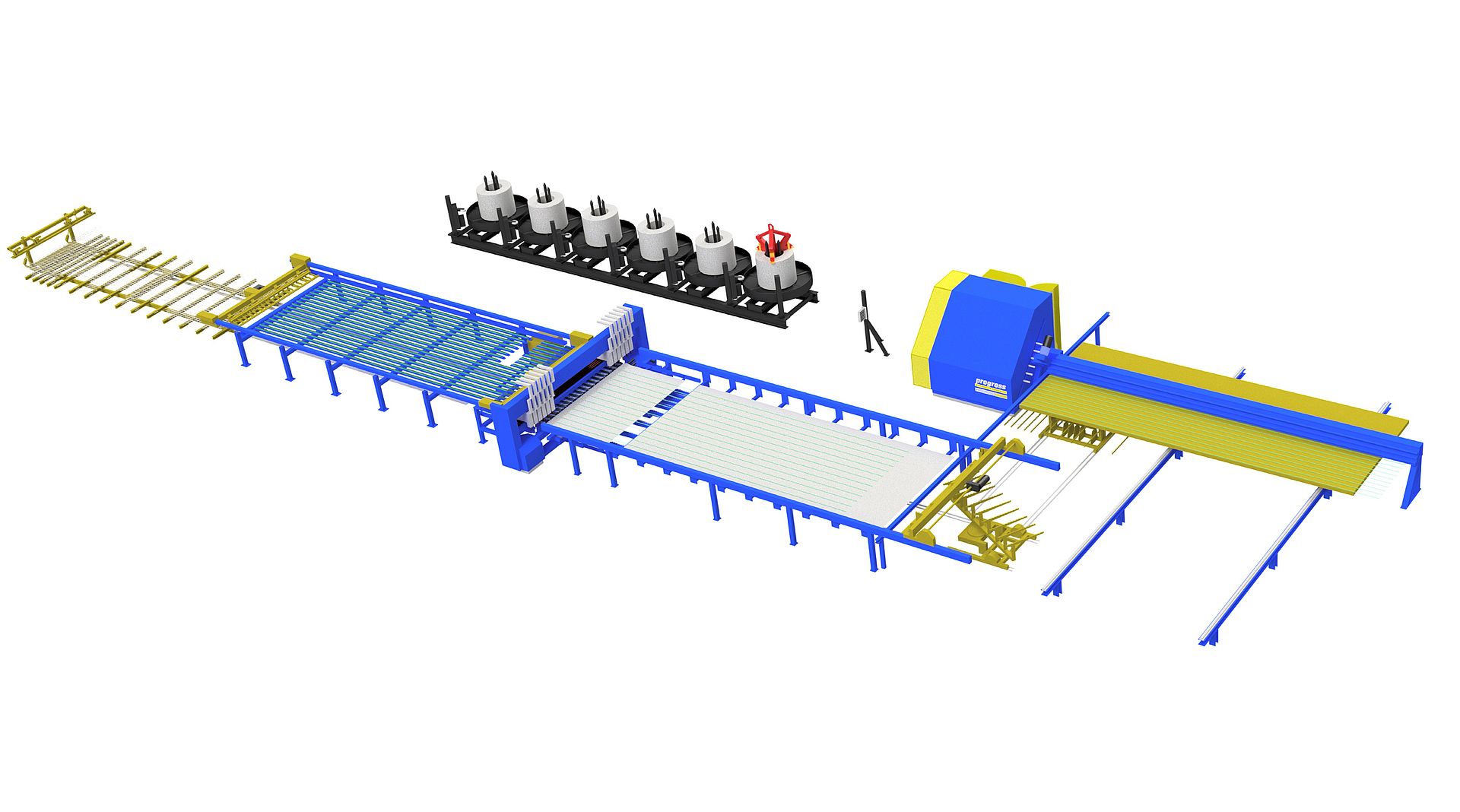

The bespoke mesh welding machines of the BlueMesh series are flexible production plants for welding bespoke mesh from coil according to individual specifications. These cost-efficient machines are especially well-suited for factories with extremely high quality demands and moderate outputs. These production plants are characterized by a very high level of technology – but also by energy efficiency, low space requirements, and affordability. Depending upon your needs, the plant can be combined with fully automatic bending systems and logistical solutions.

Technical data

| M-System BlueMesh | |

| Diameter range | 4 - 20 mm (#6) |

| Longitudinal wire spacing | 50, 25, variable spacing |

| Straigthening machine | MSR |

| Possible wire diameters | 6 (8) |

| Diameter changeover time | 6 sec. |

| Number of welding heads | 2 - 6 |

| Flexible meshes | included |

| Connected load | approx. 185 kVA |

| Plant dimensions | approx. 38 x 12 m |

High performance

Low energy and space requirements

Efficiency

Bespoke Mesh

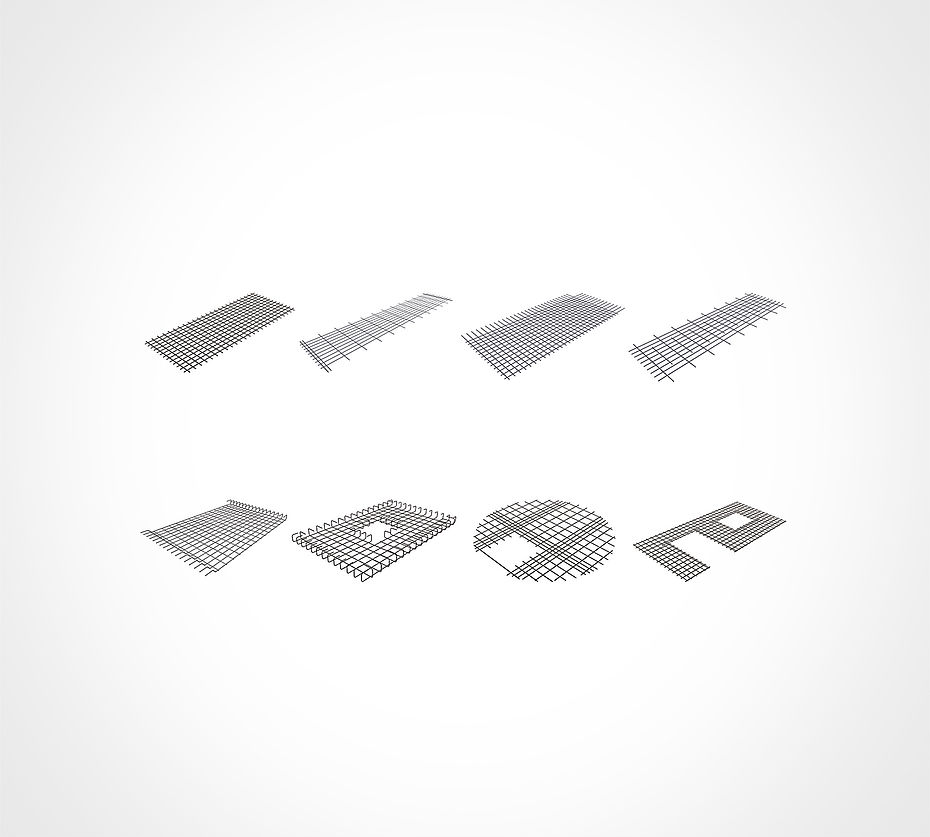

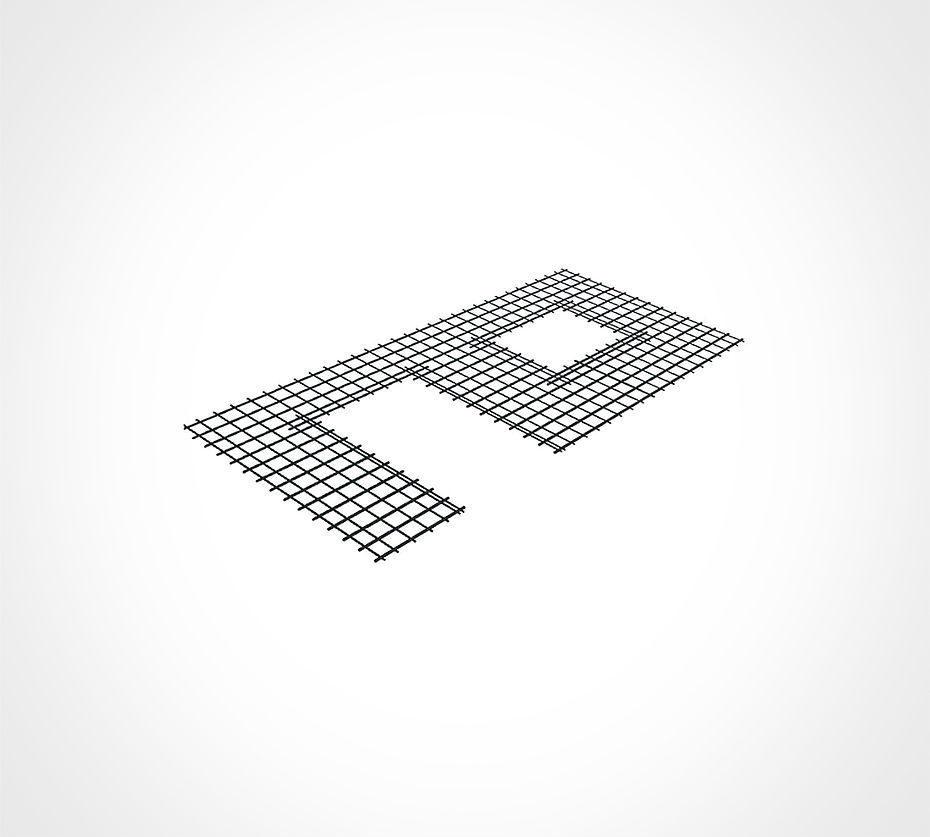

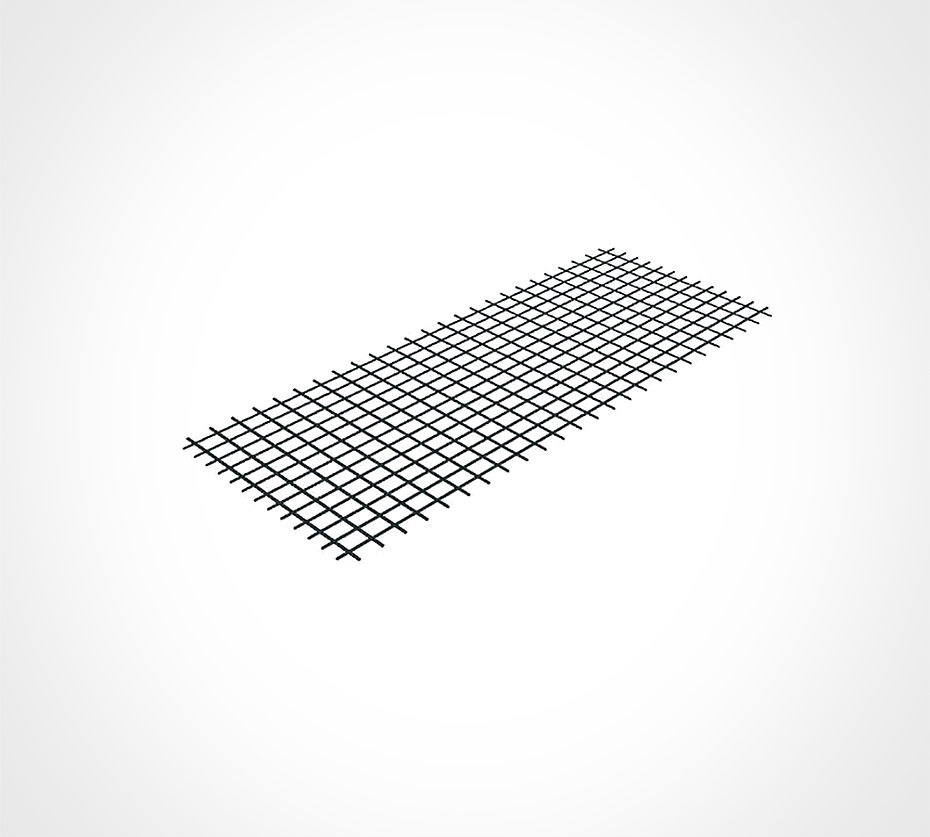

Bespoke mesh is used ad static reinforcement in the concrete element. For example, bespoke mesh is used in two-dimensional precast concrete elements, such as wall and ceiling elements. A distinction is made between predominantly static and non-static effects in welded mesh.

Mesh is produced to suit exactly the customer-specific requirements for the prefabricated units.

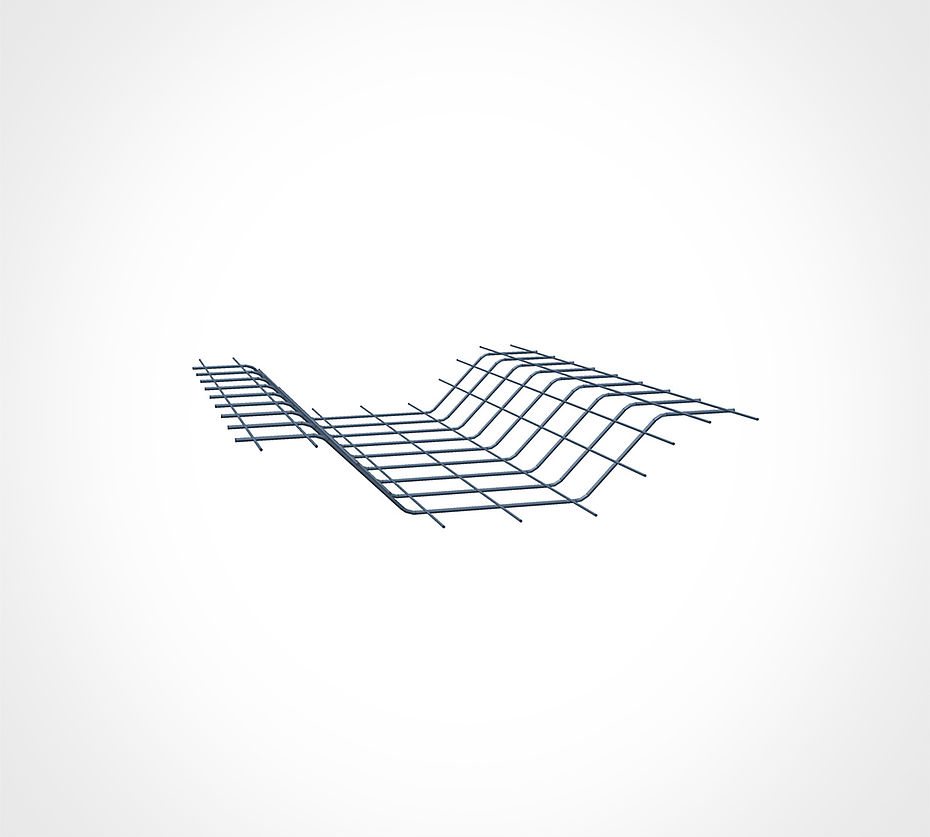

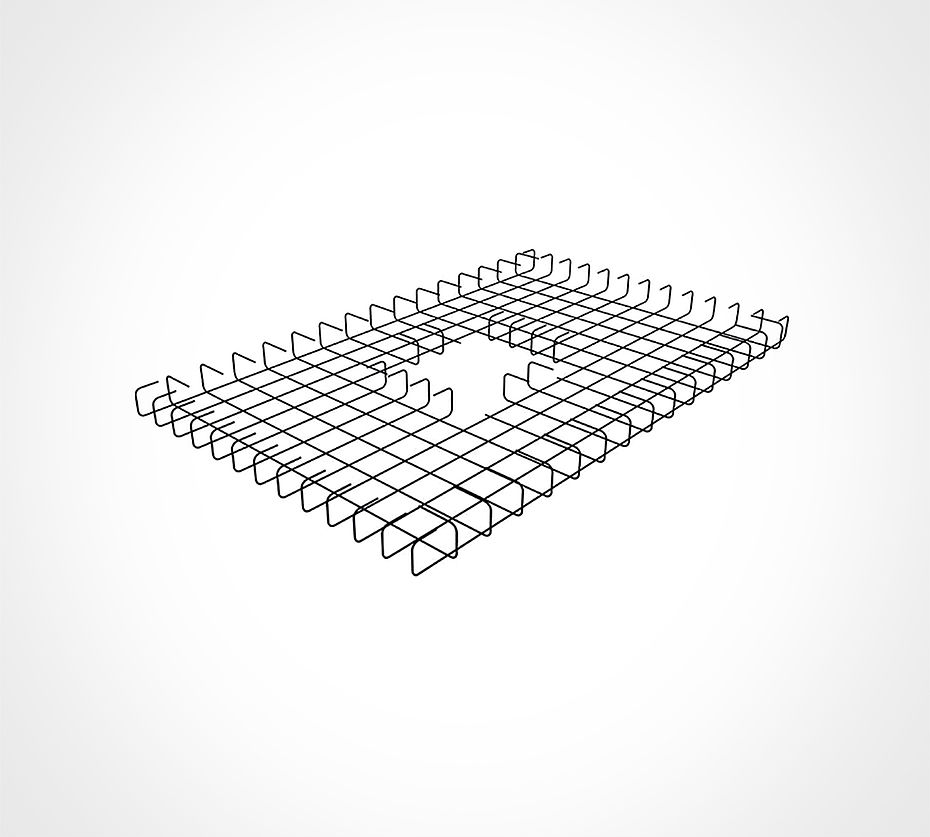

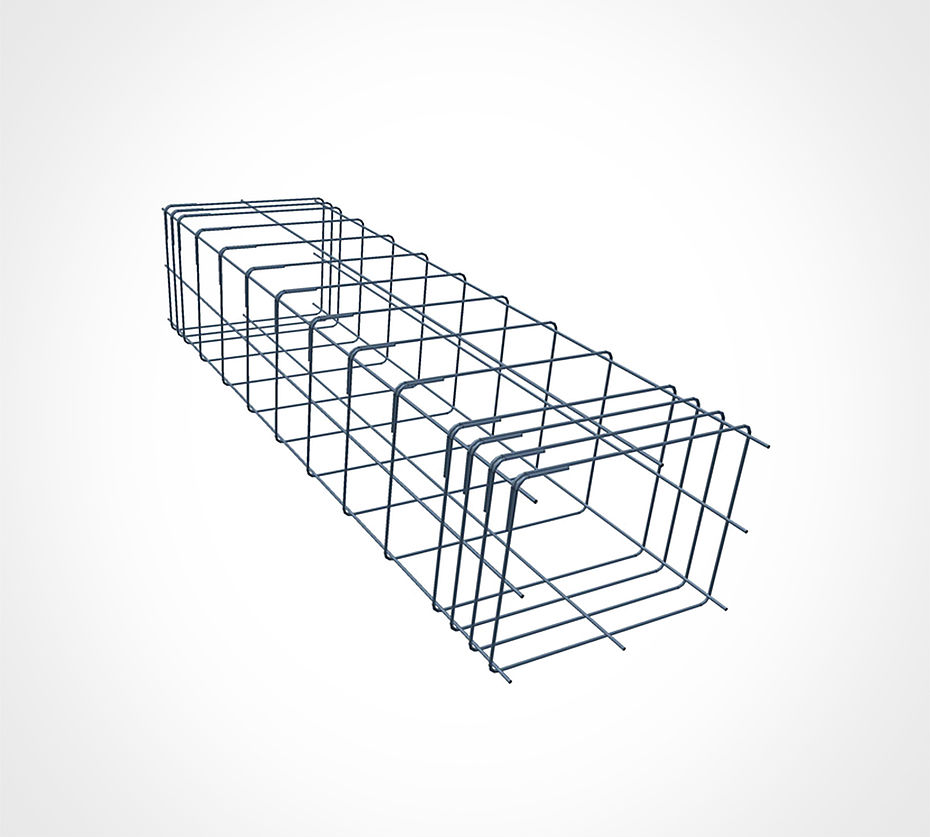

Bent bespoke mesh and cages are manufactured from mesh, which is bent after production of the mesh. The mesh is either welded together or intertwined (fastened). It is used, for instance, for pillars, columns, girders, pipe installation and for connections between walls.